Introduction

|

Warning |

|

Failing to follow the operating

instructions or to receive training from an authorized Toro distributor

may result in death or serious injury.

- To maximize the safety, performance,

and proper operating of this machine, carefully read and fully understand

the content of this Operator's Manual.

- For more information on safe operating

practices, including safety tips and training materials, go to www.Toro.com.

This manual

covers the installation and maintenance of the charging station for

the Turf Pro series robotic mowers and Range Pro

series ball pickers.

Note: Information about the peripheral wires and loop wires is located

in the Operator’s Manual for each mower.

This

charging station is intended to be used by professional, hired operators

for autonomous, programmable lawn care. It is designed

for charging the batteries on the Turf Pro and Range Pro autonomous

robots. Using the autonomous robots, battery, charging

station, and base station for purposes other than their intended use

could endanger you and bystanders.

Read this information carefully

to learn how to operate and maintain your product properly and to

avoid injury and product damage. You are responsible

for operating the product properly and safely.

Getting Help

Visit www.Toro.com for product

safety and operation training materials, accessory information, help

finding a dealer, or to register your product.

Whenever you

need service, genuine Toro parts, or additional information,

contact an Authorized Service Dealer or Toro Customer Service and have the

model and serial numbers of your product ready. These numbers are

located on the serial plate on your product.

Write the numbers in the space provided.

With your mobile device, you can

scan the QR code on the serial number decal (if equipped) to access

warranty, parts, and other product information.

| Model Number: |

|

Serial Number: |

|

Manual Conventions

This manual identifies potential

hazards and has safety messages identified by the safety-alert symbol,

which signals a hazard that may cause serious

injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight

information. Important calls attention

to special mechanical information and Note emphasizes

general information worthy of special attention.

Safety Alert Classifications

The safety-alert

symbol shown in this manual and on the machine identifies important

safety messages that you must follow to prevent

accidents.

Safety-alert symbol appears above

information that alerts you to unsafe actions or situations and is

followed by the word DANGER, WARNING,

or CAUTION.

|

Danger |

|

Danger indicates an imminently

hazardous situation which, if not avoided, will result in death or serious injury.

|

Warning |

|

Warning indicates a potentially

hazardous situation which, if not avoided, could result in death or serious injury.

|

Caution |

|

Caution indicates a potentially

hazardous situation which, if not avoided, may result in minor or moderate injury.

Product Overview

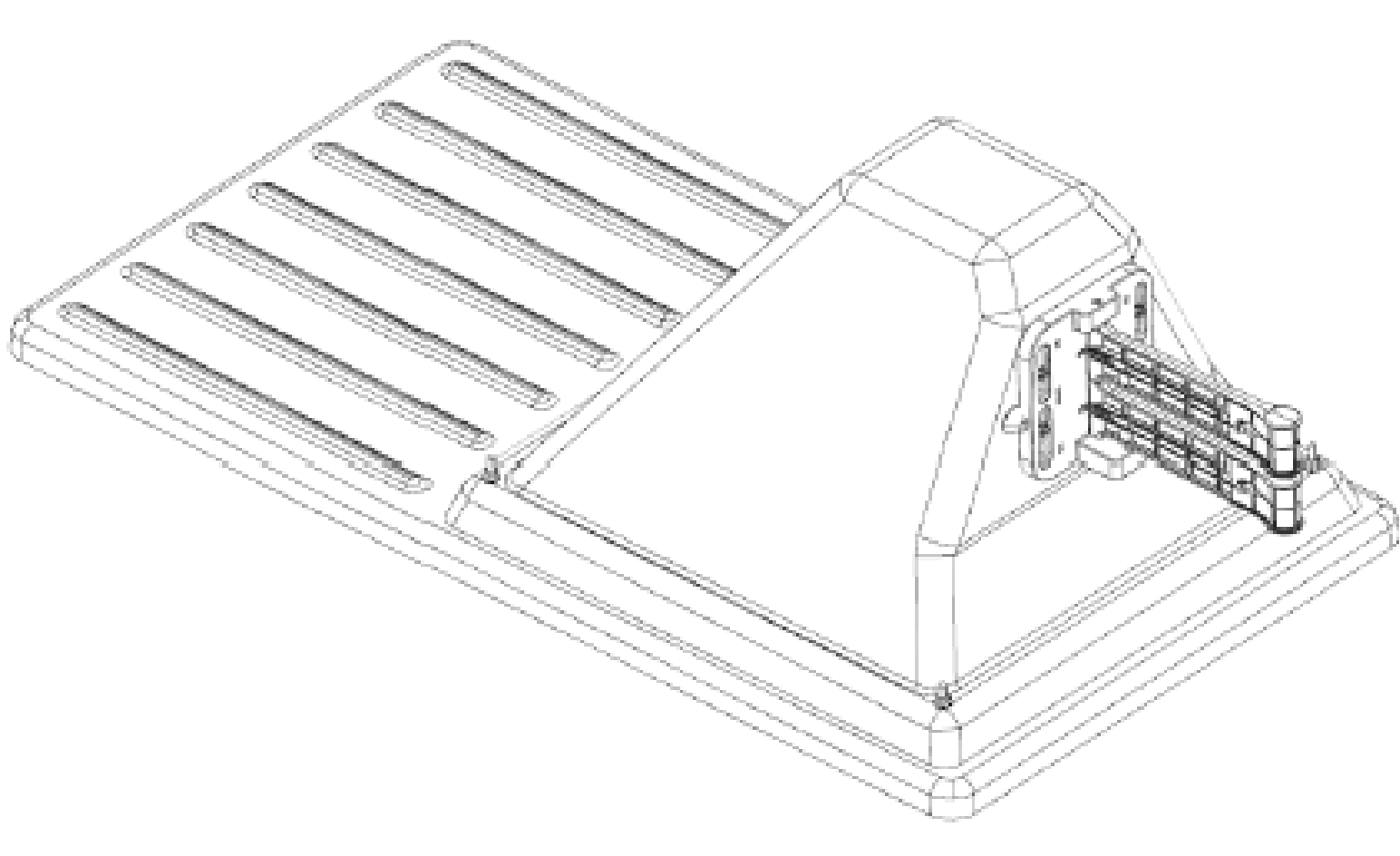

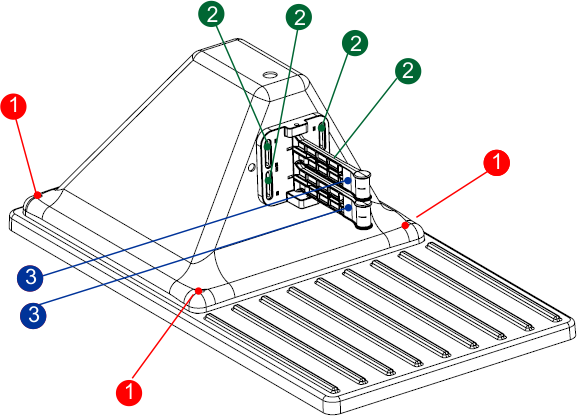

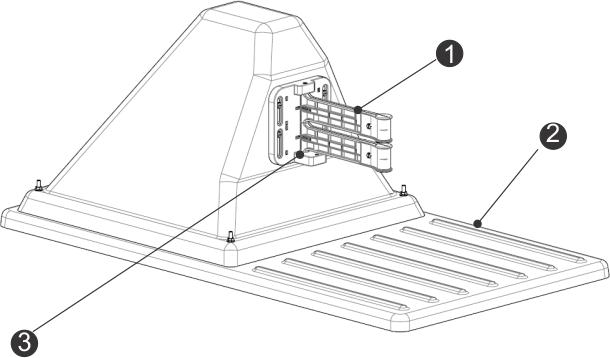

Charging Station Components

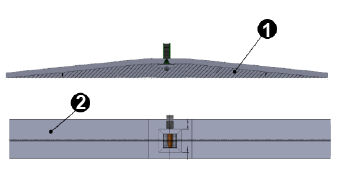

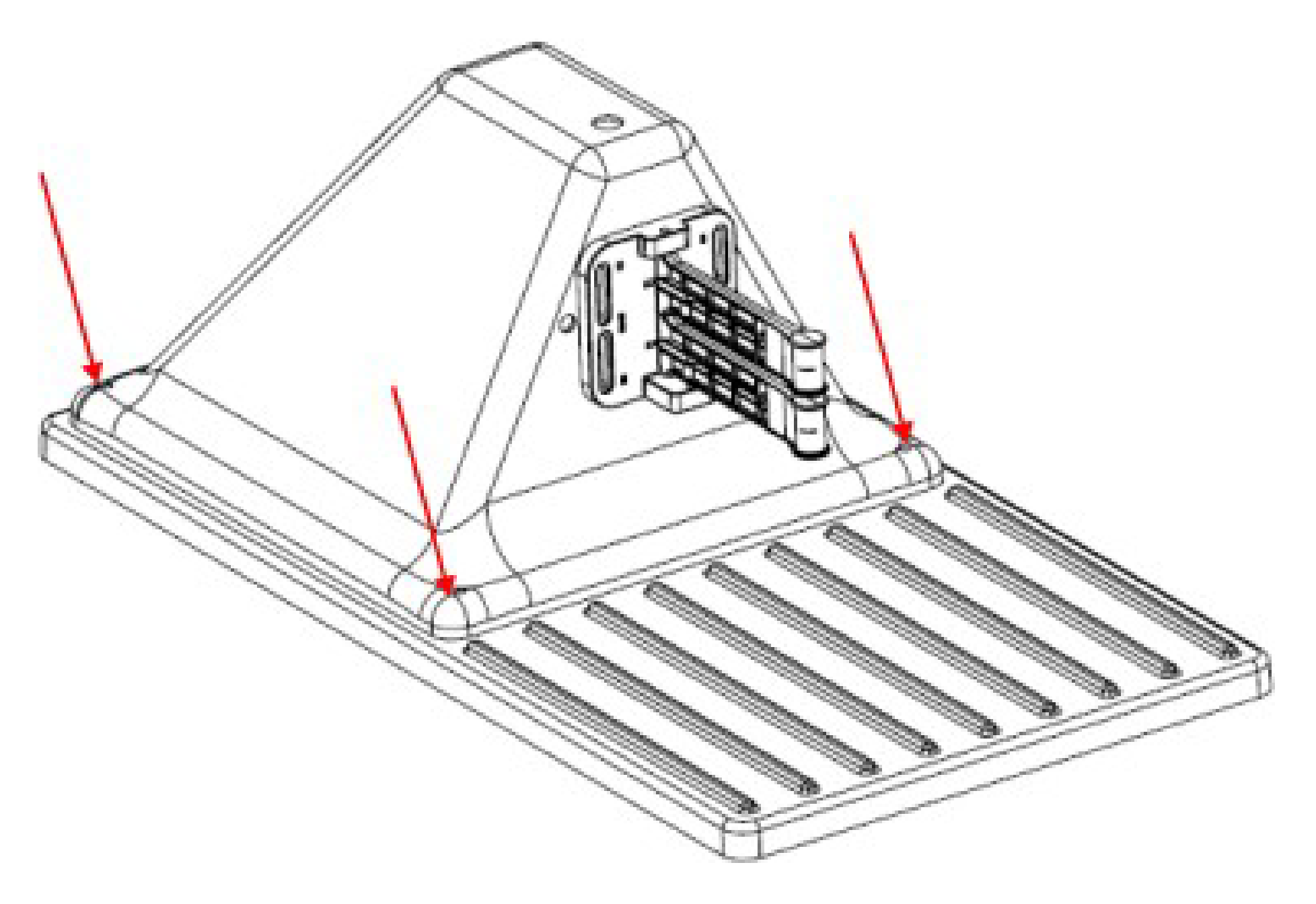

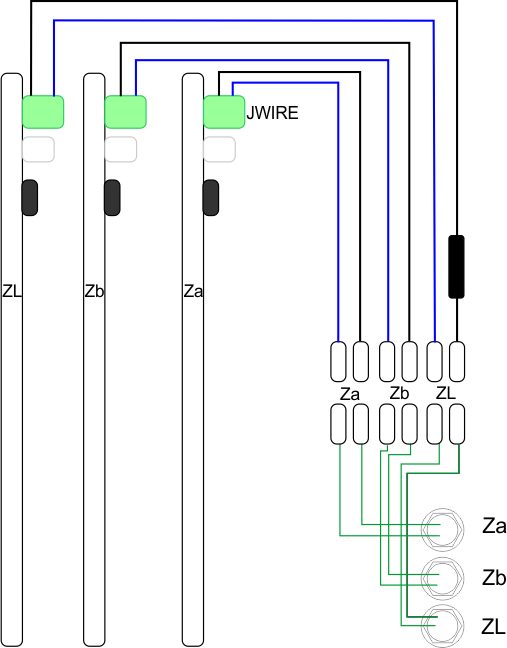

Note: Model 30914 is shown

G520730

- Charge

arms

- Base

- Occupation

sensor

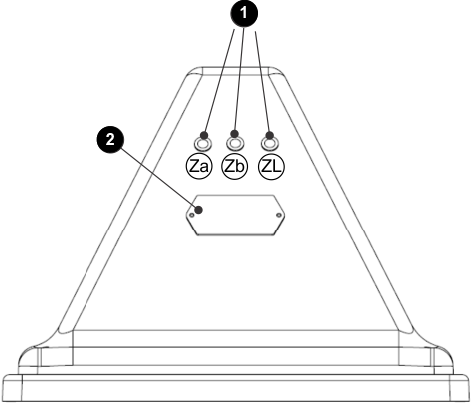

Rear View of the Charging Station

Note: Model 30914 is shown

G526516

- LED indicators

- Identification

label

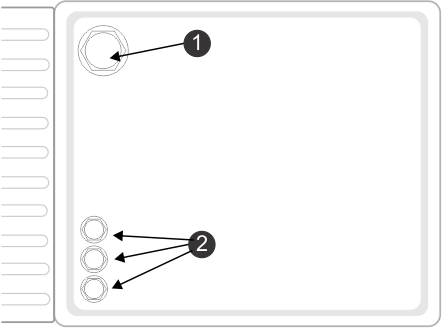

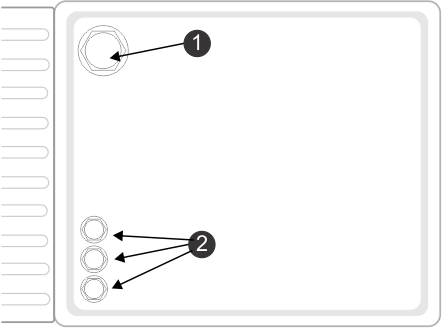

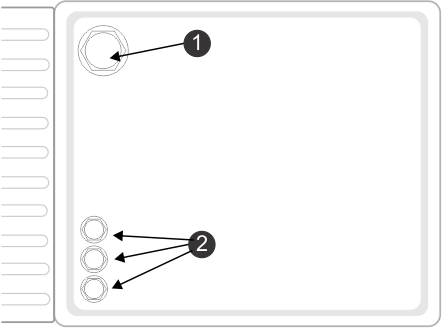

Bottom View of the Charging Station

G520732

- Power-cable

input

- Peripheral-cable

input

Occupation Sensor

The occupation

sensor is an optional feature indicating that the charging station

is occupied in charging a robot. This particularily

important when using multiple ball-collecting robots.

LED Indicators

The LED indicators

show the current state of each wire. Refer to the following table.

| Green - blinking

|

The wire is operating normally. |

| Red - blinking

|

No peripheral wire can be detected.

The wire may have been cut or is too long.

|

| Red - steady

|

This indicates a problem. The

wire may be too short (less than 200 m or 656 ft) or a problem with

the electronics. |

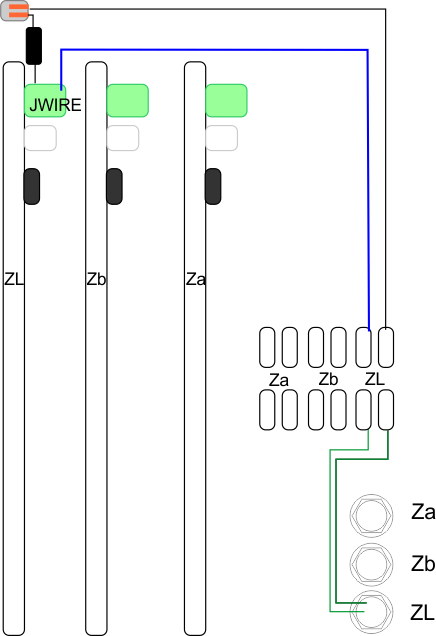

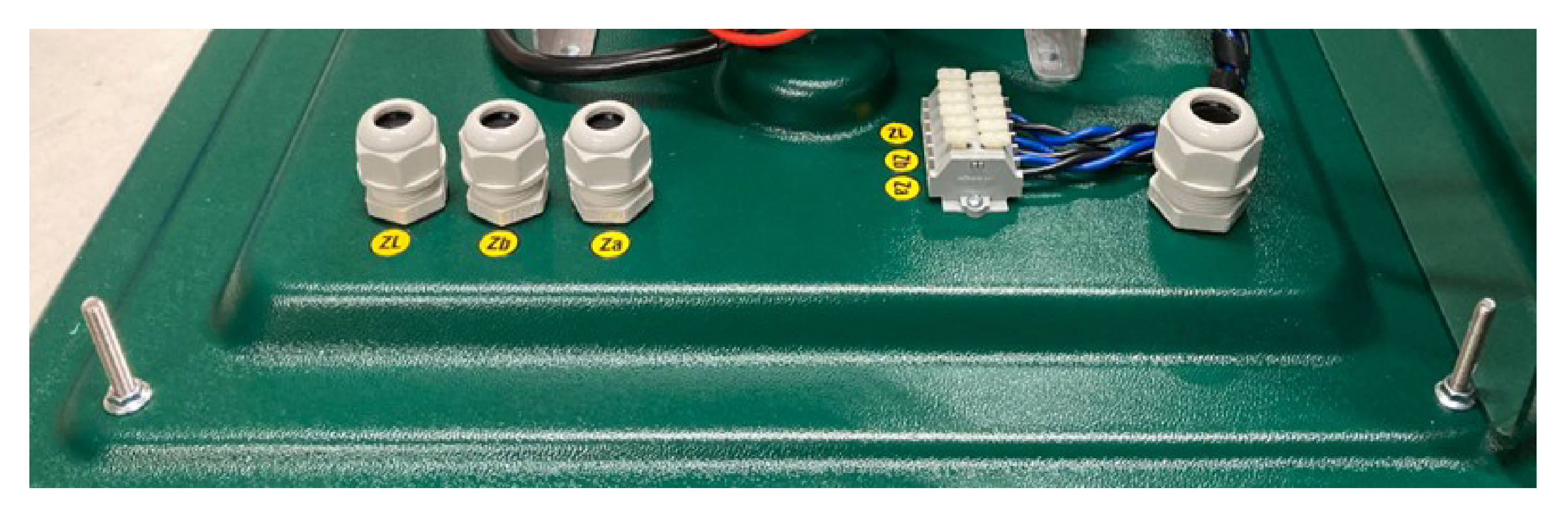

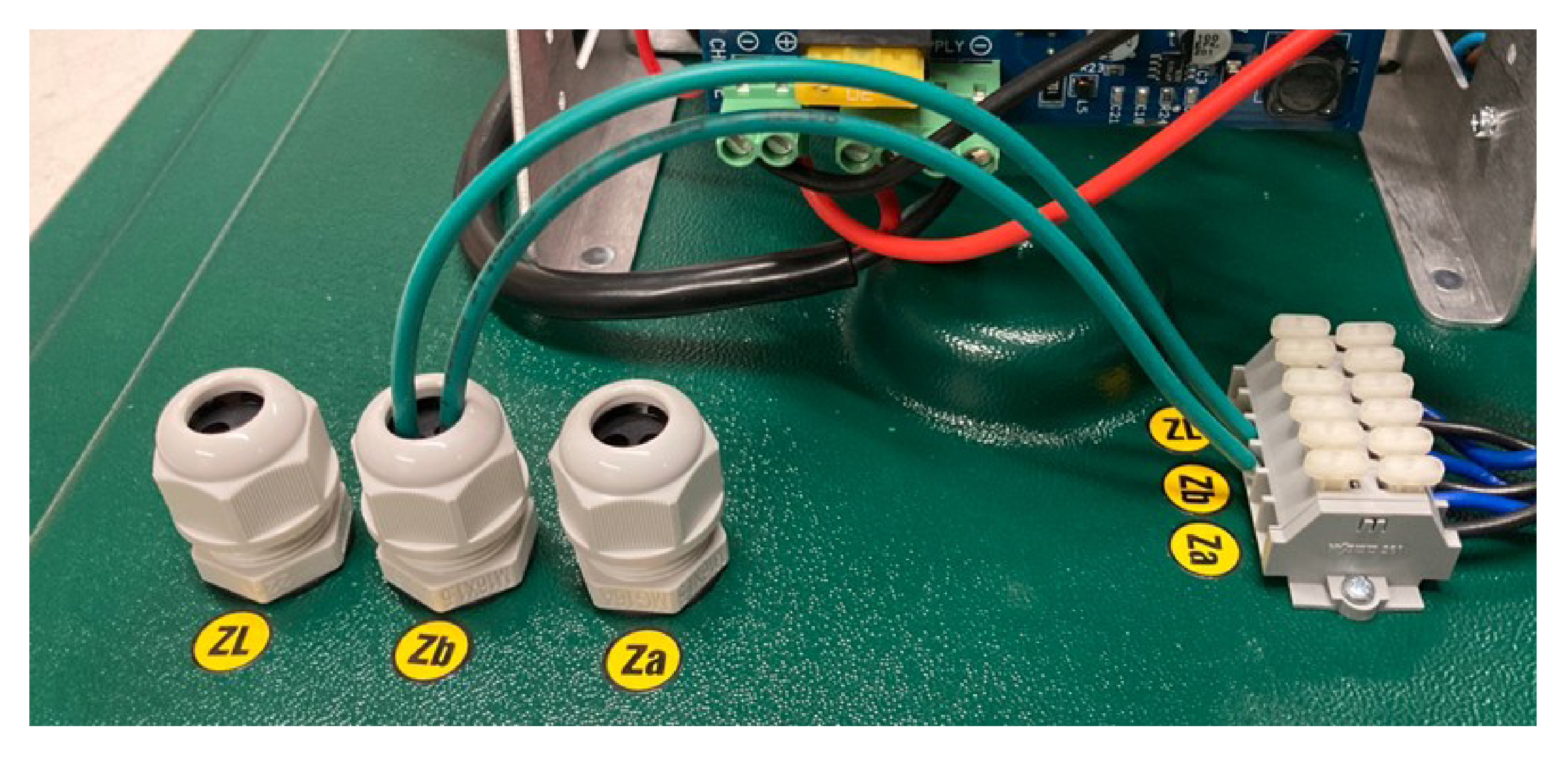

The LEDs are labelled as follows:

- ZL: The wire for the station loop

zone

- Za: The wire for the working zone

A

- Zb: The wire for the working zone

B

Note: If you are using a charging station with multiple loops and you are

not using one of the loops, the LED will blink red. To

stop the LED from blinking red, turn the channel on the

board to 9.

Stations

One station

is required for each robot to charge.

The maximum number of boards in

a station (and therefore wires that can be connected) is 3. If more

wires need to be connected (if 2 loops and 2

peripheral wires are required), install an extra channel board.

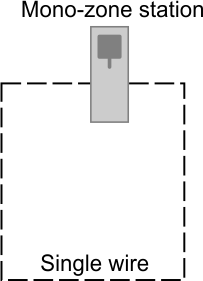

Mono-Zone Station (Loop Wire Only)

A single board is installed in

this type of station, supporting just a single wire. This type of

station would typically be used in a golf

installation, where the single wire would be the loop wire. This board

and wire is labelled ZL on the station.

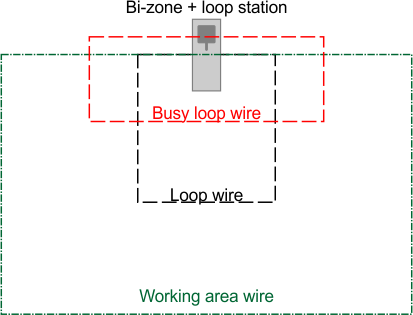

Bi-Zone and Loop Station

For golf course installation:

These 3 wires could be used for:

- A loop wire to allow the robot

to return to this station.

- A peripheral wire defining the

area in which the robot will work.

- A busy loop used when 2 ball-collecting

robots are in operation.

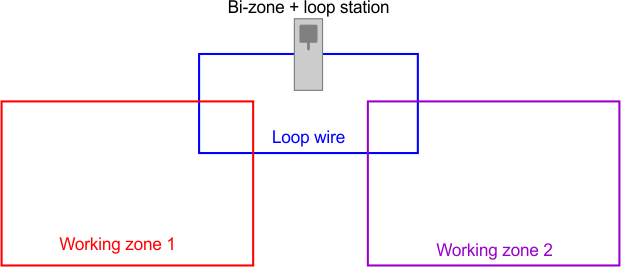

For mower installation:

3 boards will be installed in

this type of station. These boards and wires are labelled ZL (for

the loop) and Za and Zb (for the working zones).

This

station can be used for:

- A loop wire to allow the robot

to return to this station.

- 2 peripheral wires for separate

working areas.

Electronic Board

The charging station contains

a board for each wire (channel) required. A maximum of 3 boards can

be installed.

Note: If necessary, install a signal channel board in an external box.

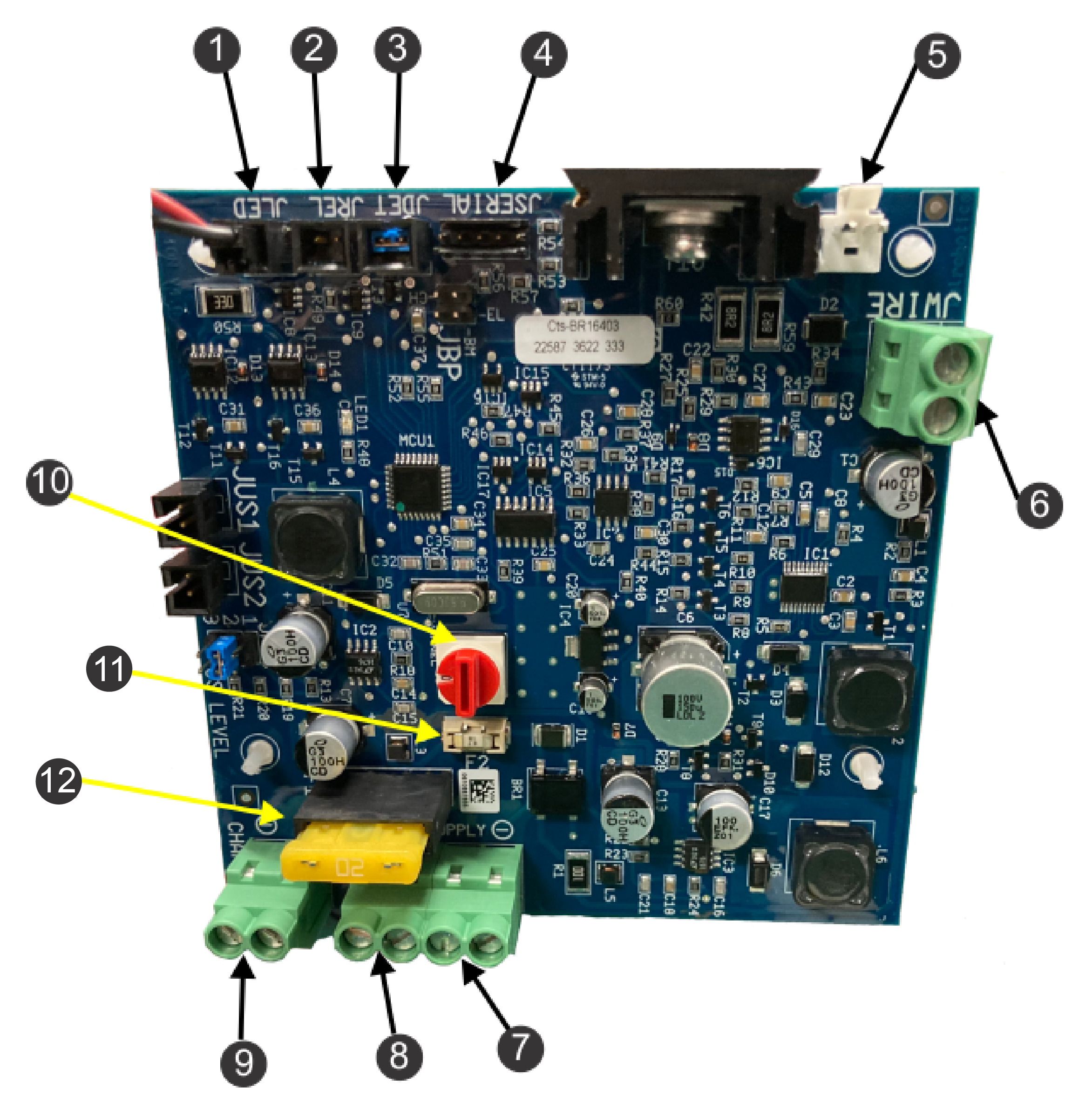

Electronic Board Components

G520838

-

Pilot LED (JLED)

-

Optional relay connection (JREL)

-

Optional presence detection (JDET)

-

PC interface for updates (JSERIAL)

-

JWire connection for surge protection

-

Peripheral wire (JWIRE)

-

Negative DC supply (JTR1)

-

Positive DC supply (JTR2)

-

32 V contact arm (JCHRG)

-

Magnetic signal channel selection

switch

-

20 A fuse (main)

-

1 A fuse (electronic board)

Specifications

Note: Specifications and design are subject to change without notice.

| Width

|

45 cm (17.7 inches) |

| Length

|

85 cm (33.5 inches) |

| Height

|

34.5 cm (13.6 inches) |

| Operating temperature |

0°C to 50°C (32°F

to 122°F) temperature protections has been implemented for higher

temperatures |

| Ingress protection |

IP54

|

| Power input

|

100-240 VAC 3.5 A 50-60 HZ |

| Charge output

|

23-32 VDC 10.7 A

|

| Output circuits

|

Class II

|

Installation

Charging Station Installation

Requirements

This is a basic installation procedure.

Each installation varies by application. Contact an Authorized Service

Dealer if you have specific questions.

One

station is required for each robot.

The installation is required to

be performed by a qualified professional.

Follow all of the national

and regional codes.

Do no bend, warp or crack the

base during the installation process.

- Develop an installation plan and

a map of the site. If the installation is for ball picker, make sure

to determine the area needed for the ball

drop.

- Identify a location for installing

the AC power supply, station loop peripheral wire(s), and field zone

peripheral wire(s).

- There should be no risk of flooding

after heavy rain.

- Obstacles must be more than 6

m (19.7 ft) away from the charging station. For more details concerning

water obstacles, refer the following section

that details positioning the station near water.

- When GPS navigation is being used,

the station should be positioned in the following ways to optimize

the GPS precision:

- to the south of the site, if the

site is in the northern hemisphere

- to the north of the site, if the

site is in the southern hemisphere

- The charging station must lie

within the range of the 4G RTK base or Wi-Fi repeater and receive

a good signal level. A signal level of

1.2 is required for the robot to be able to leave the station and

signal level of 2.0 is required for 4G RTK.

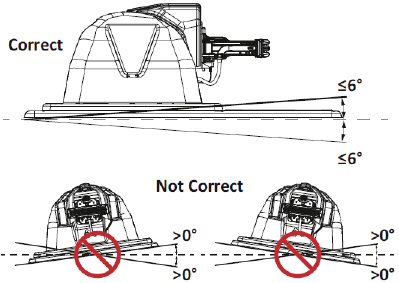

- Install the charging station on

flat ground where flooding or water accumulation will not occur.

Note: If the entire field is on a slope, install the charging station on

a flat portion at the top. The robot has no brake when

it is in charge mode and can slide away from the

charging arm contacts if the longitudinal slope is greater than 0°.

Positioning the Charging Station

Near Water

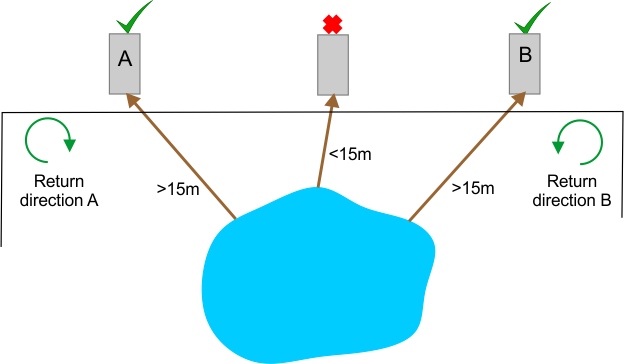

The charging station must be located

at least 15 m (49 ft) from the water's edge.

The figure below summarizes

critical factors associated with the placement of the charging station

near a water feature.

In the situation illustrated above,

two possible locations for a charging station have been shown. The

robot should return to the station from the

direction away from the water. So if the charging station is located

in point A, the robot must return to it in

a clockwise direction. If the charging station is located in point

B, the robot must return to it from a counter-clockwise

direction.

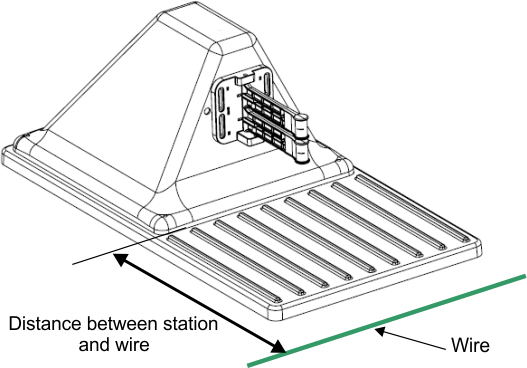

Charging Station and Wire Distance

Turf Pro 300 only: The distance between the

station and the loop wire is 0.57 m (22.4 inches).

Turf Pro 500 and Range

Pro series only: The distance between the station and the loop wire is 0.67 m (26.4

inches).

Connecting the Peripheral and

Loop Wires

-

The installation must be performed

by a qualified professional.

Follow all national and regional

codes.

If necessary, remove the lid by

removing the nuts.

-

Feed the

wire(s) through the base of the station.

of the station.

Note: Model 30914 is shown.

G520732

- Power

cable input

- Peripheral

cable input

The label for

the circuit can be seen on the inside of the station base.

Note: Za and Zb are for the peripheral wires around the working areas.

ZL is for the loop wire.

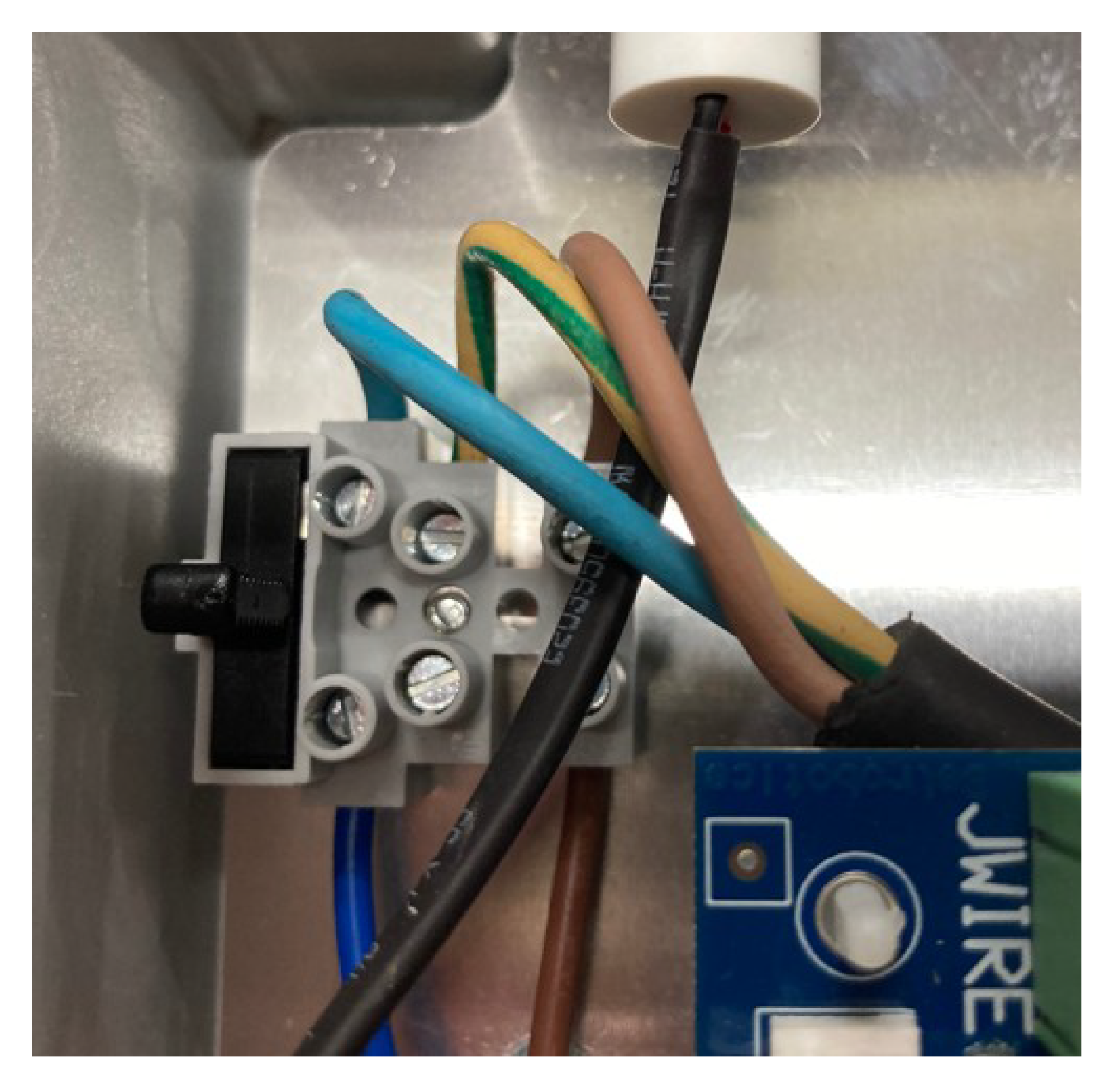

-

Connect the

2 wires to the corresponding connections on the station as shown.

A schematic

wiring diagram for the peripheral and loop wires is shown in the figure.

Connecting the Power Supply

-

The installation must be performed

by a qualified professional.

Follow all national and regional

codes.

Note: The charging station may only be connected to a supply circuit protected

by a Residual Current Device (RCD) with a tripping

current of less than 30 mA.

Open the station by removing the

nuts on the lid.

-

Thread the

power cable through the base .

.

Note: Model 30914 is shown below.

G520732

- Power

cable input

- Peripheral

cable input

-

Note: The station needs a good ground connection.

Connect the 3 wires to the corresponding

connection in the station as shown in the following figure.

- Live: upper connection (brown)

- Ground: middle connection (green/yellow)

- Neutral: lower connection (blue)

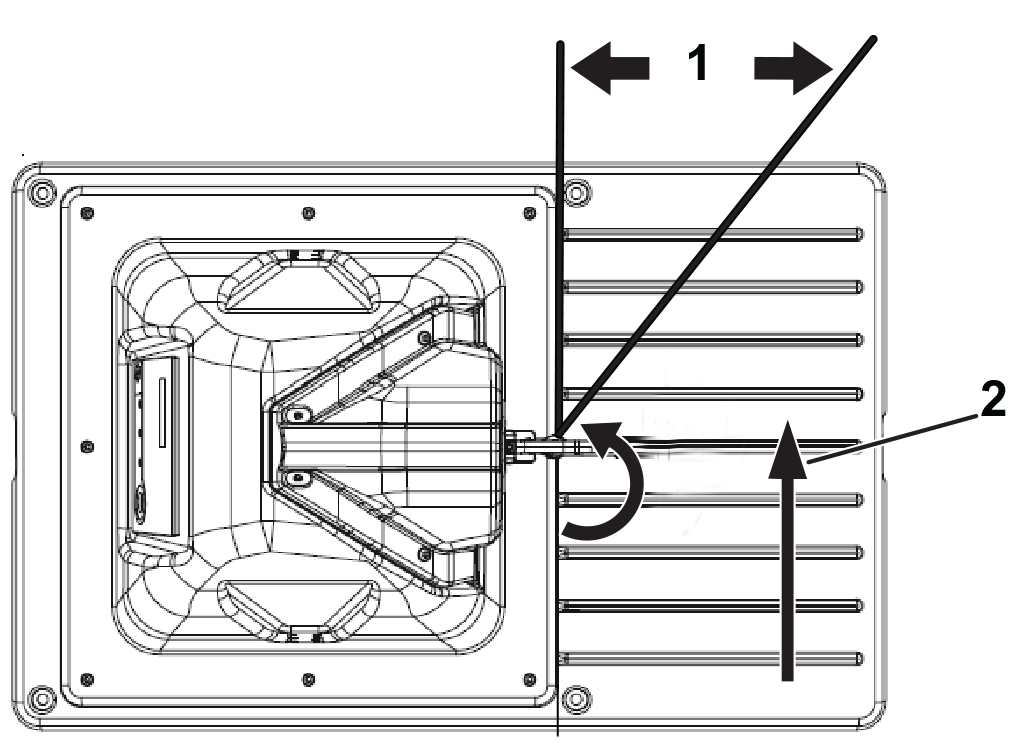

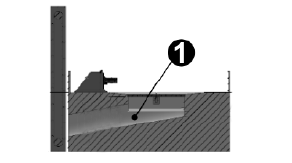

Station and Robot Alignment

The position of the charging

station must ensure that when the robot is in place:

- The height of the arms has been

set to make good contact between the charging station and the contacts

on the robot.

- The angle of the charge arms is

at 30° to 45°. The robot can charge in either direction.

G541732

-

30° to 45°

-

Robot direction

Multiple Station Installation

When considering the position

of multiple stations, the criteria listed below should be taken into

account.

In the case of a multi-station

installation, it is recommended to place the stations as a group in

a location with easy access to a power supply.

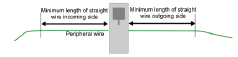

The

station should be positioned on a straight section of the peripheral

wire with defined minimum free distances on both

the incoming and outgoing sides.

- The minimum length of wire on

the incoming side is 3.5 m (11.5 ft).

- The minimum length of wire on

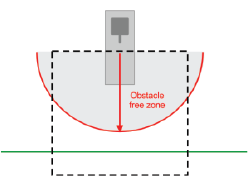

the outgoing side is 3.5 m (11.5 ft).

An obstacle

free zone of at least 6 m (20 ft) is required.

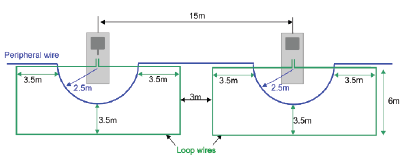

Multiple Stations Position

The dimensions

associated with the positioning of multiple stations are shown below.

The

minimum distance between stations is 15 m (49 ft).

In the example

shown below, the peripheral wire bends around the station with a 2.5

m (8 ft) radius. This is to ensure that a

working robot does not collide with a robot that is parked at the

station.

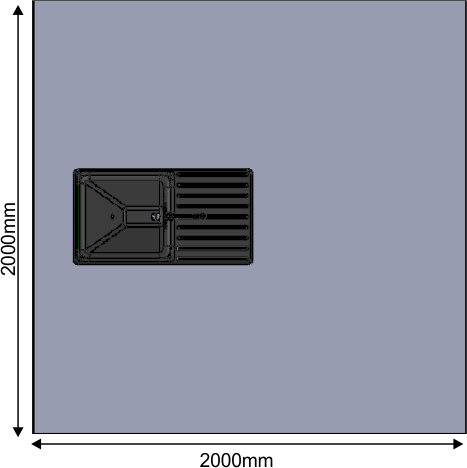

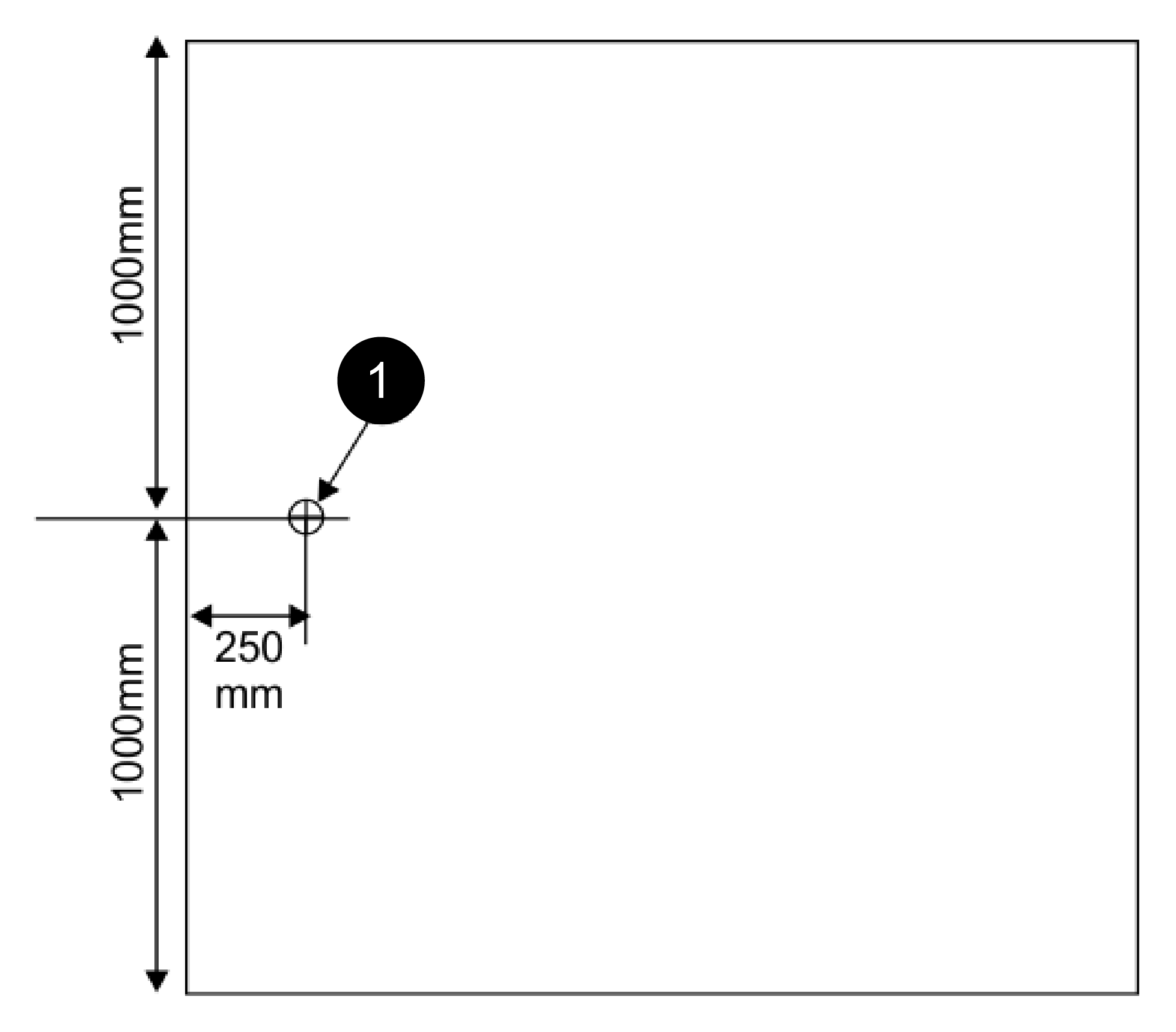

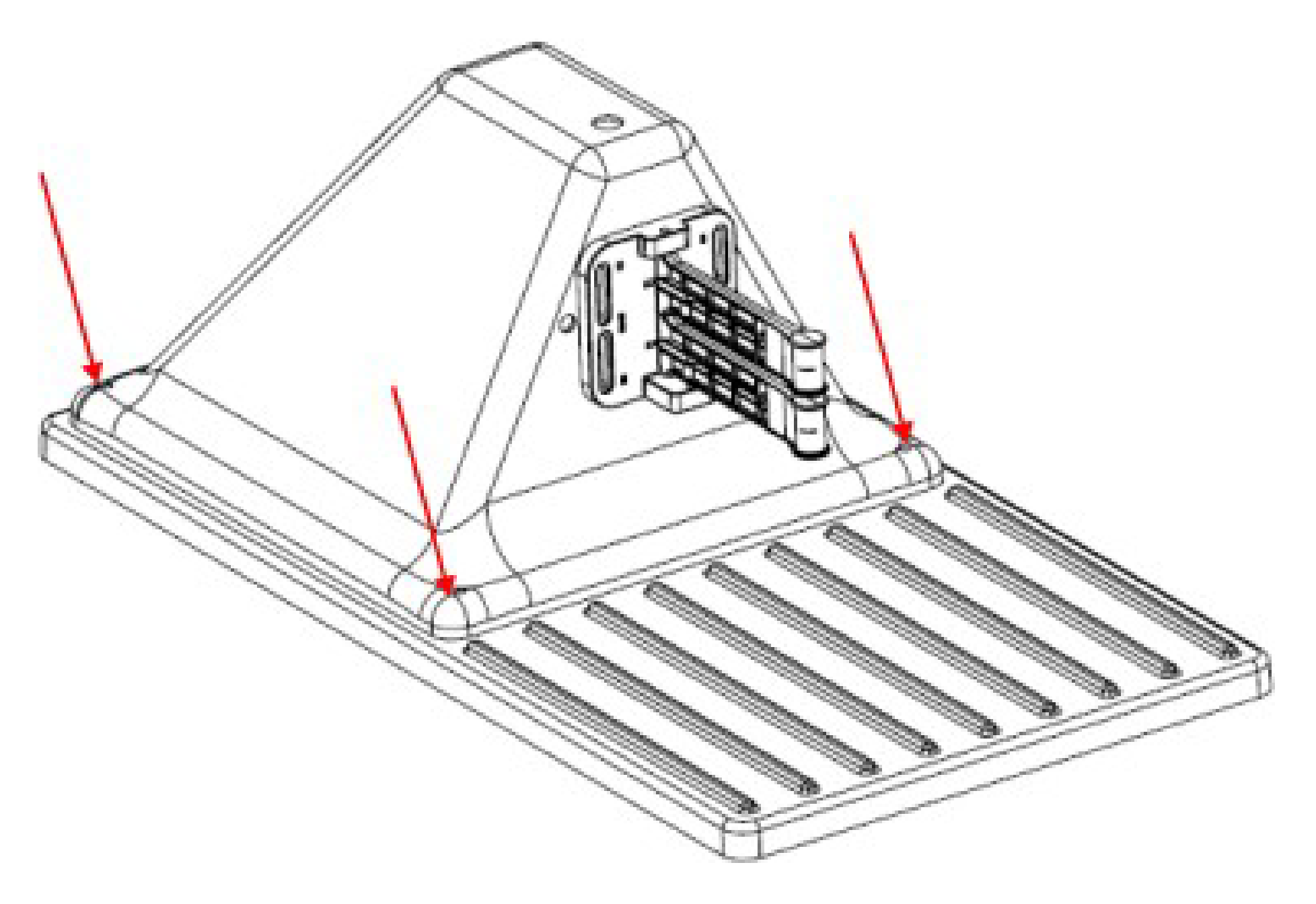

Mounting the Charging Station

on Concrete

You can mount the charging station

on a concrete base.

Note: The concrete should contain no reinforcing mesh or any other metallic

parts.

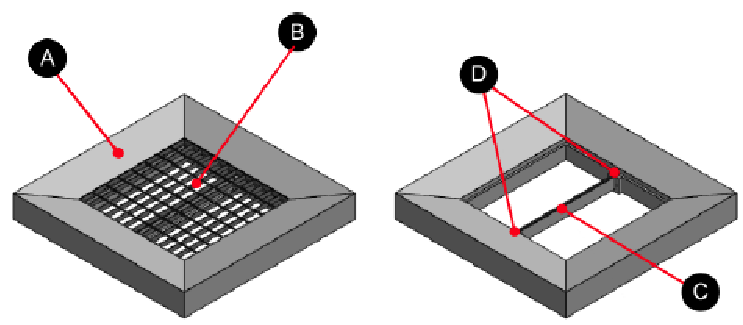

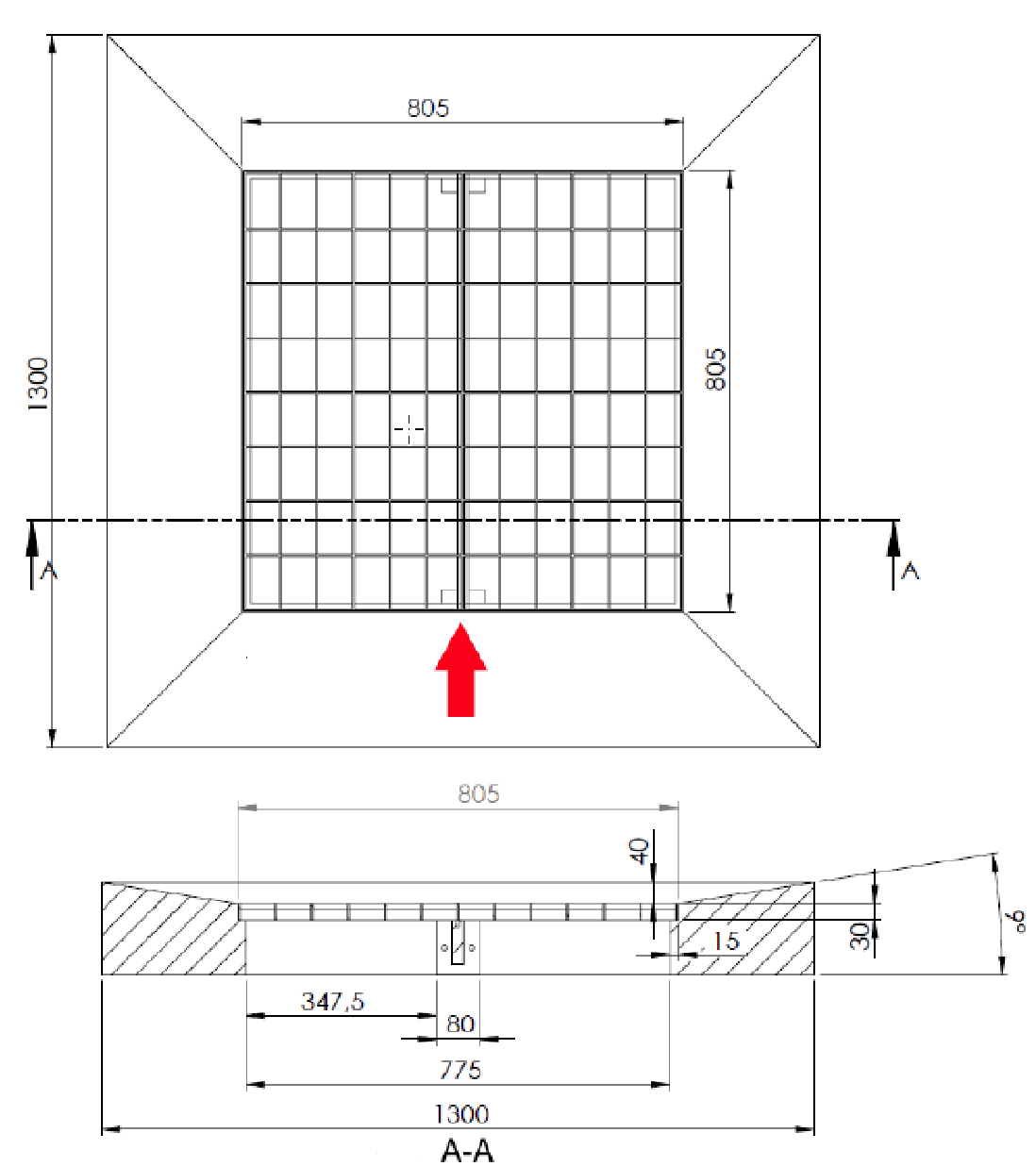

The following figures show the

recommended dimensions for this base.

G520986

-

Location of the power supply for

the base

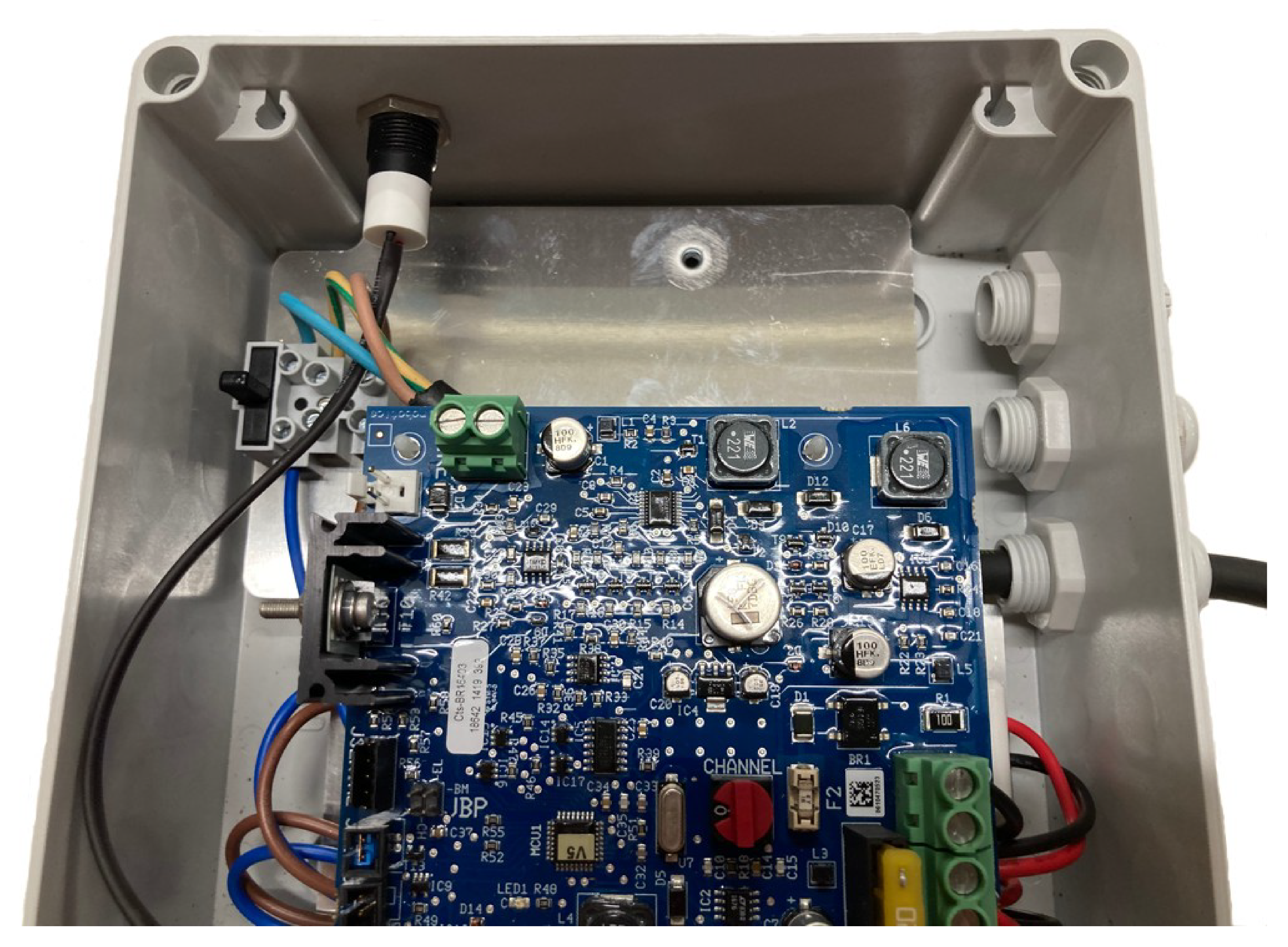

Installing the Channel Board Outside

of the Charging Station

If multiple wires for working

areas and loops are required, or if a wire is located at a significant

distance from the charging station, it may be

necessary to install a channel board closer to the wire rather than

in the charging station. This can save on the

total length of wire required.

It may also be necessary to install

an external channel board, near the charging station, if there is

not sufficient space in the charging station.

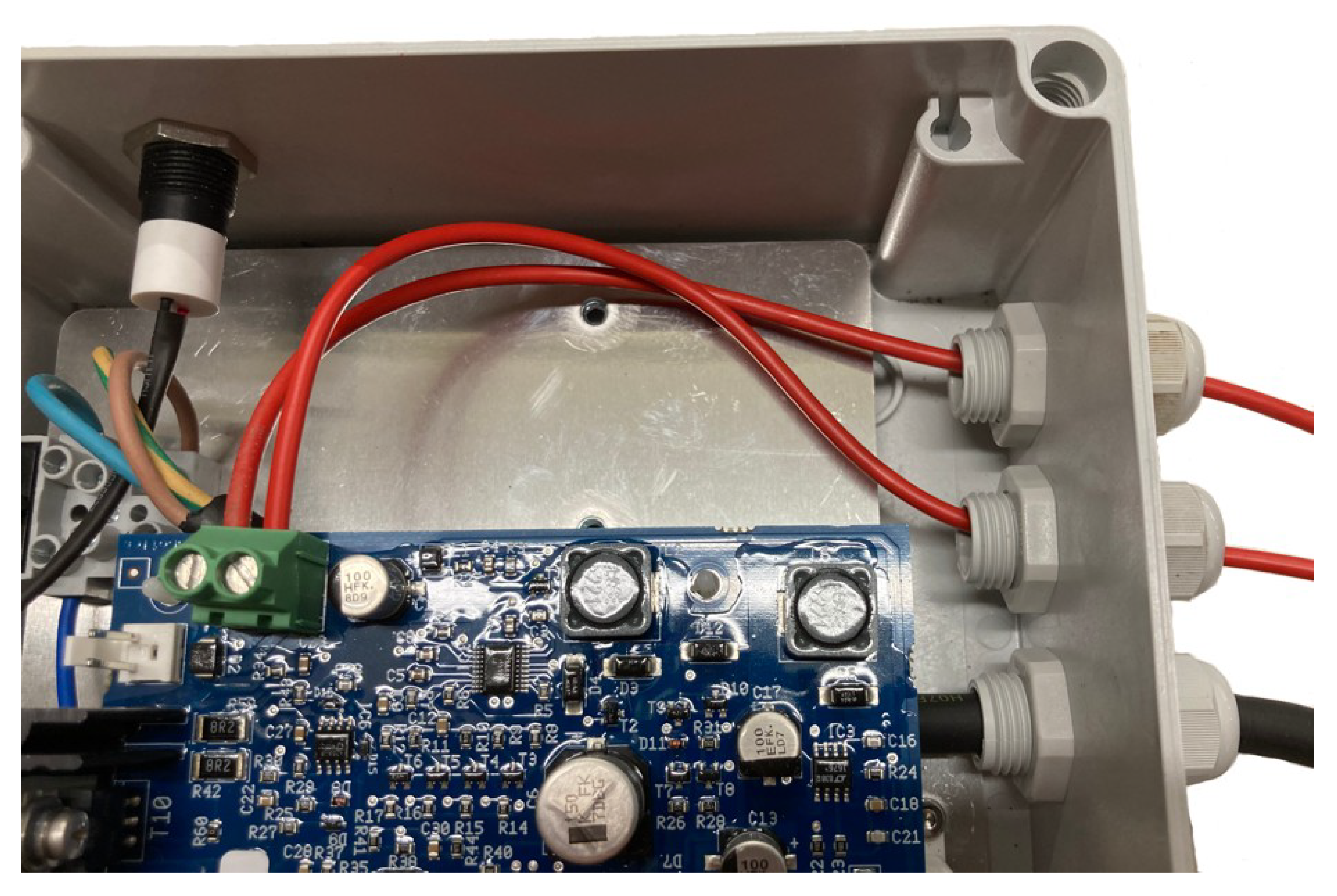

-

Insert the

mains power cable through the gland as shown in the following figure.

-

Connect the

live (brown), ground (green/yellow), and neutral (blue) cables to

the connectors in the box, as shown in the following

figure.

-

Insert the

2 peripheral wire cables through the glands as shown in the following

figure.

-

Connect the

peripheral wire cables to the connectors on the card as shown in the

previous figure.

Installing an Inductor in the

Charging Station

If the total length of any of

the wires is less than 200 m (656 ft), it is necessary to install

an inductor in the charging station. This is

important when using a small loop to return the robot to the charging

station.

Note: The loop wire circuit is labelled ZL and has the inductor installed.

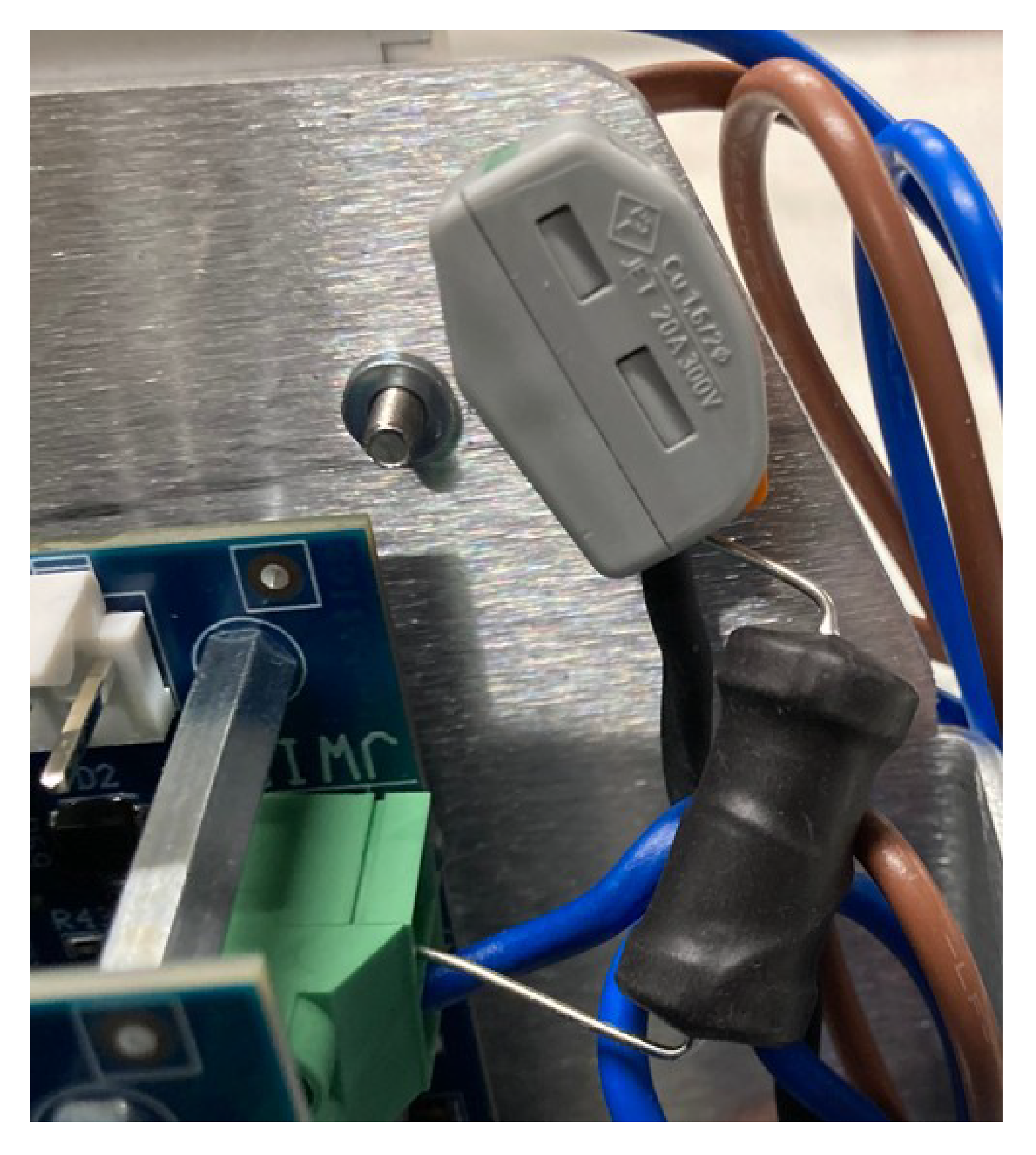

-

Place the

inductor in series with the peripheral wires. One end must be connected

to the station connection; the other must

be connected to the peripheral wire.

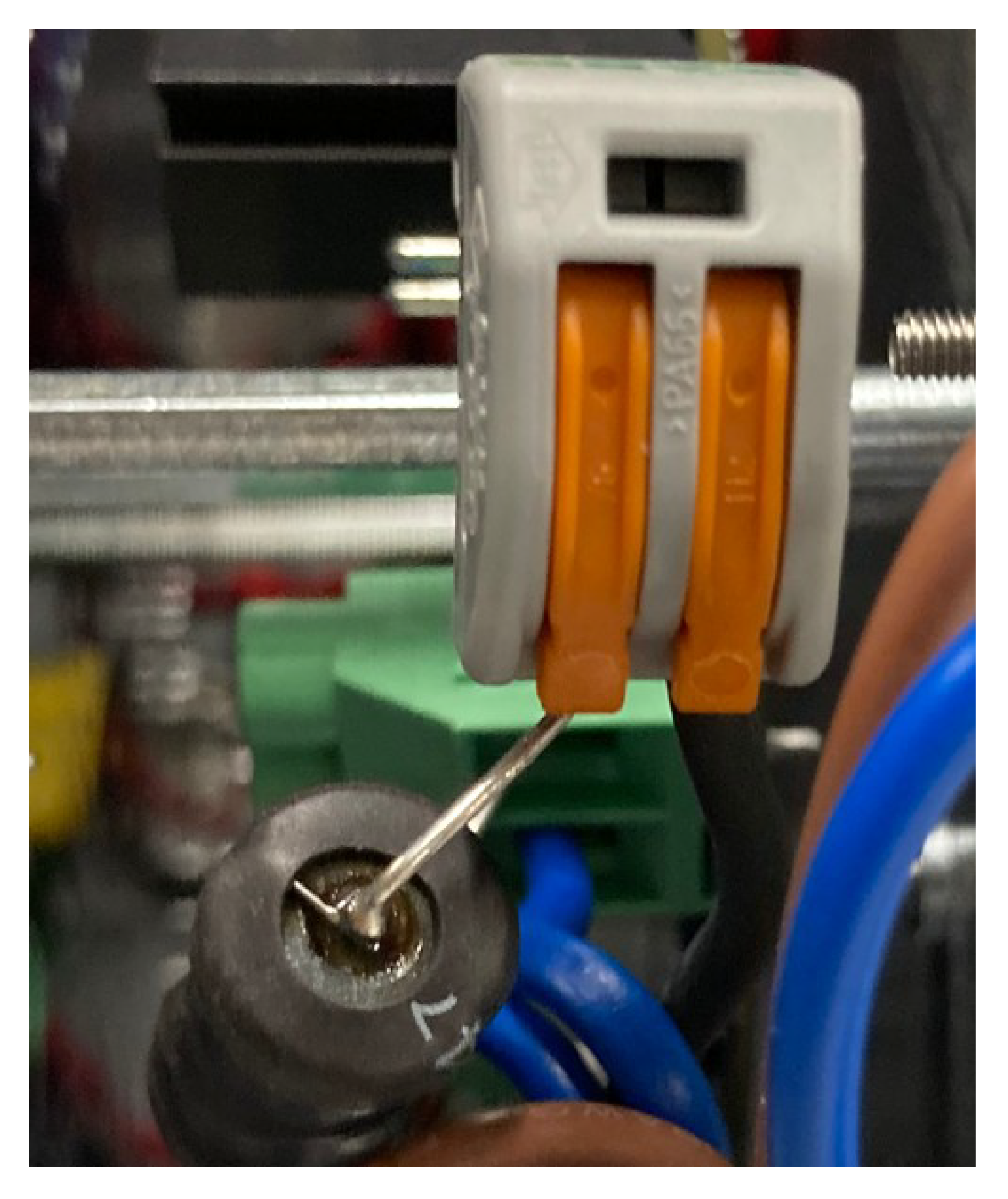

In the example

show in the following figure, an end of the inductor is connected

directly to the JWIRE connection on the ZL

card.

The other end

of the inductor is connected to a side of the 2-way connector. The

other end of the 2-way connector is connected

to the peripheral wire.

of the station.

of the station.

.

.