-

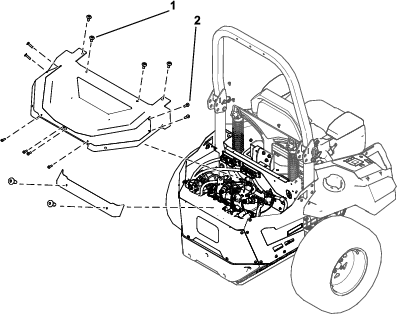

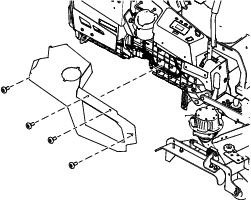

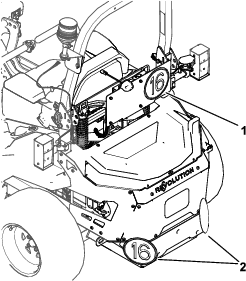

Remove the 4 Torx screws securing the side cover on

the right side of the machine. Repeat on the left side. Retain all

parts.

-

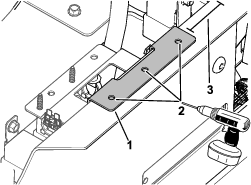

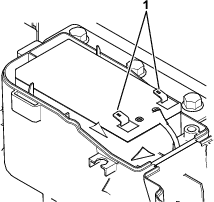

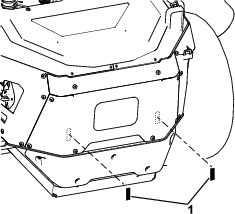

Remove the nut and bolt securing the electrical plate

cover and remove the cover. Retain all parts.

-

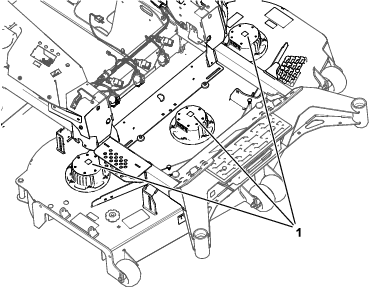

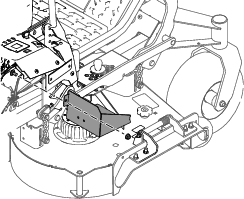

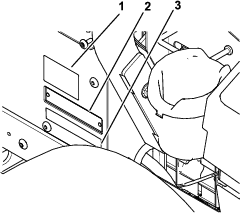

Starting from the back of the machine, lay the EU

Road light kit wire harness on to the license plate mount and light

assembly. Route the headlight, horn, and light switch connectors through

the left side.

Note: If machines have MyRIDE, route the harness through the opening.

-

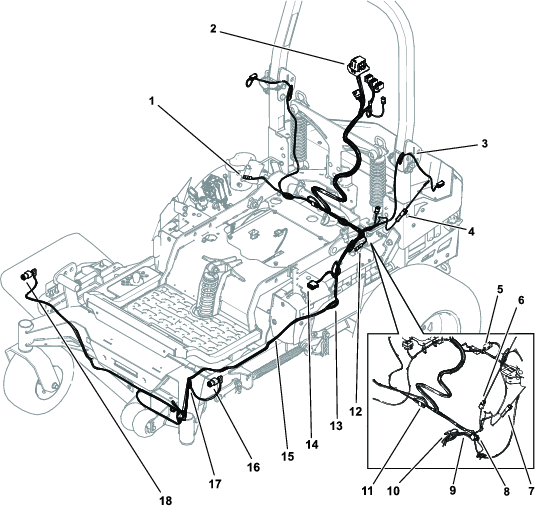

Route the headlight, horn, and light switch through

the left side of the chassis behind the console.

-

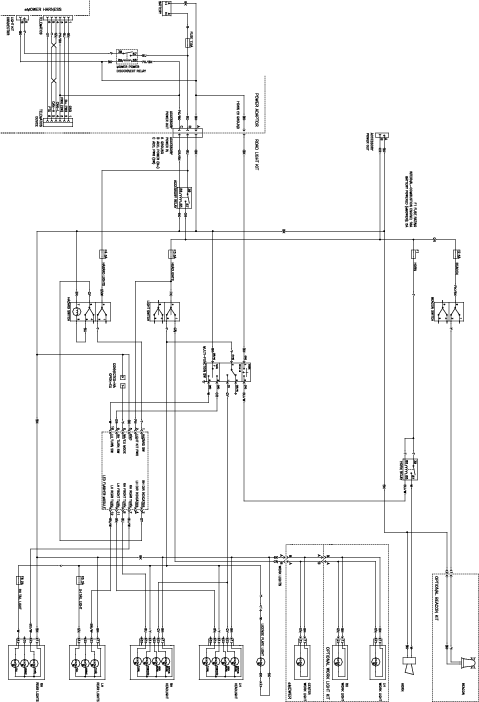

Connect the 12-pin connector on the EU Light kit wire

harness to the control lever assembly left connector.

-

Route the horn headlight cable on left side chassis

rail and under the toe board, avoiding interference with the MyRide

platform.

-

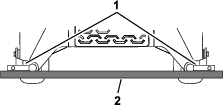

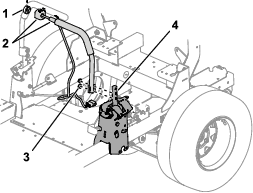

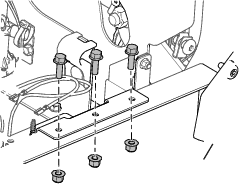

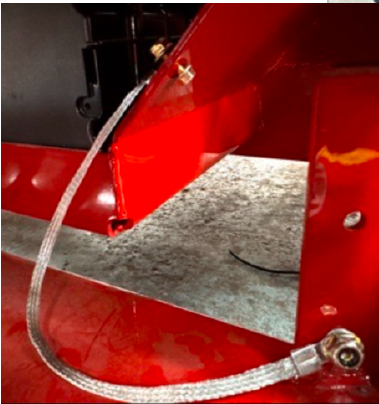

Route the harness along the height-of-cut bar at the

front of the machine and around the anchor point to the left chassis

rail interior below the operator platform.

-

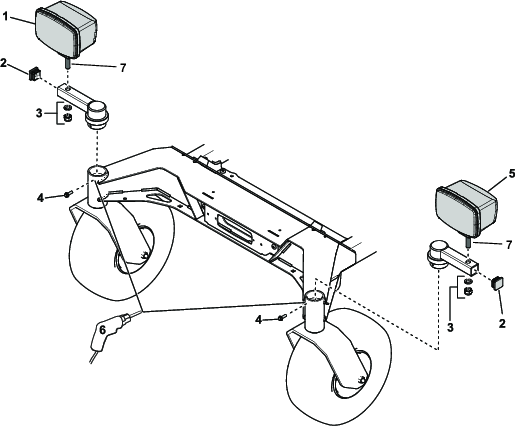

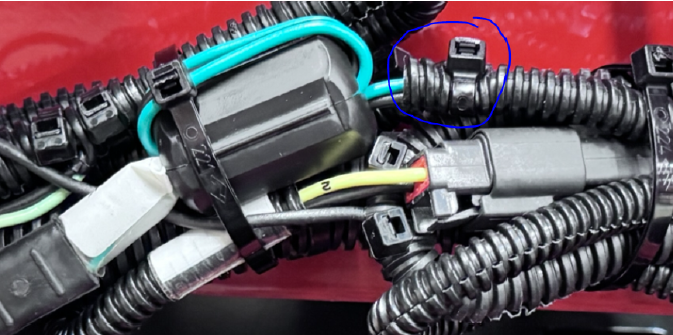

Identify the left and right front light connectors.

Mark the connectors.

Note: The right connector has blue, yellow, gray, and black wires.

The left connector has brown, yellow, grey, and black wires.

-

Route the front light connectors to their corresponding

lights.

-

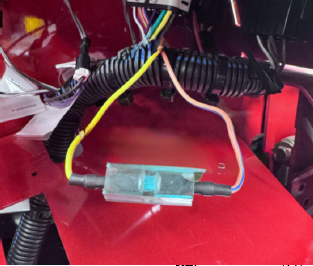

Connect the front light connectors on the light kit

harness to the front lights. Ensure that the harness conduit is secure

to the shell.

-

Connect the terminals white wire to (+), black wire

to (-).

Note: Due to the horn blocking access to the existing tie-down point,

the cords can be secured on the side of the chassis.

-

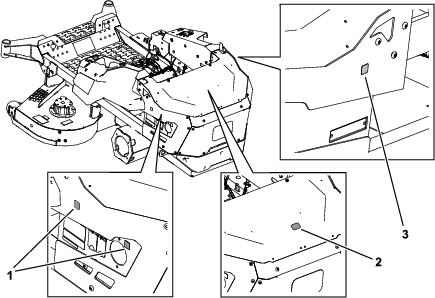

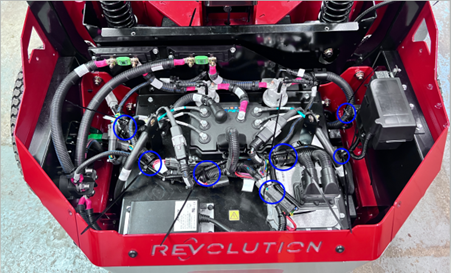

Lay the wiring harness connections to their approximate

positions at the machine rear.

-

Connect the beacon wire harness to the beacon connector

on the light kit wire harness.

-

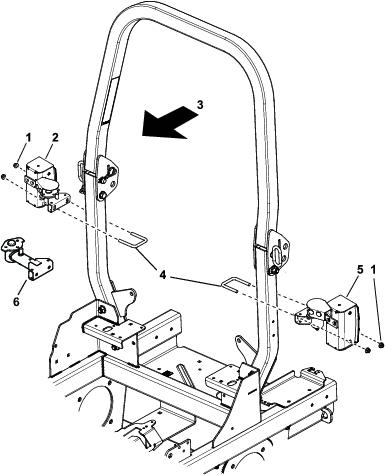

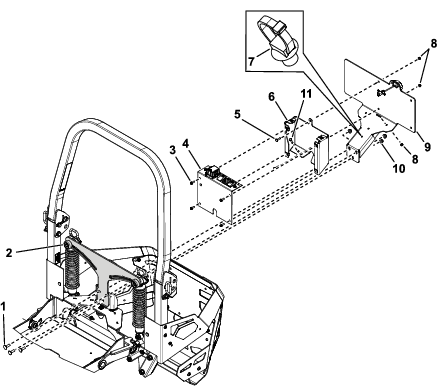

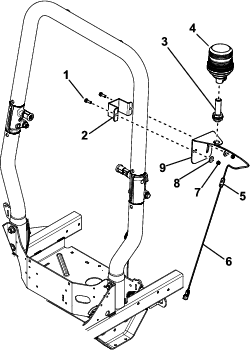

Route the left-rear light connector up the front of

the roll bar next to the beacon wire harness.

-

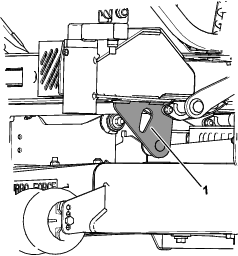

Route the connector through the rear light mount and

connect it to the rear light mount with 2 screws (#10 x 1-1/4 inches).

-

Secure the bracket height until the red light is approximately

90 cm (35 inches) above the ground.

-

Repeat the previous steps to install the rear right

light.

-

Secure the rear light leads and beacon harness to

the ROPS frame.

Note: Allow some slack in the beacon cable to allow the ROPS frame

to be folded.

-

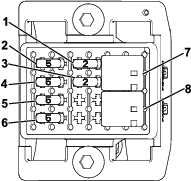

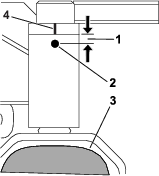

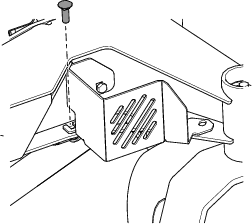

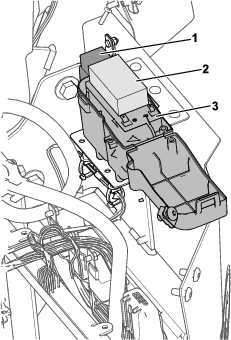

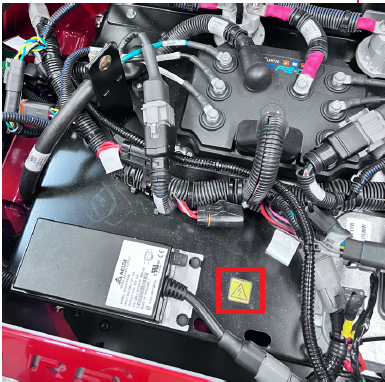

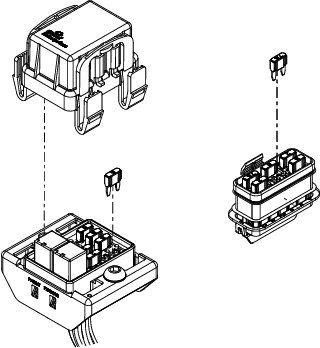

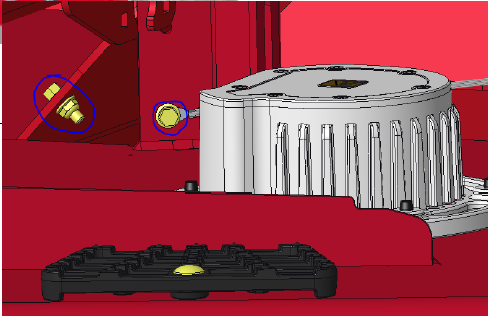

Open the main machine harness fuse box and remove

the fuse (5 A). Retain the fuse.

-

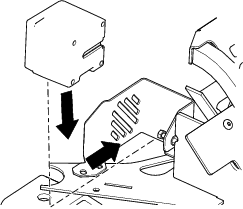

Install the mini-blade fuse (7.5 A) in place of the

fuse (5 A) and close the cover.

-

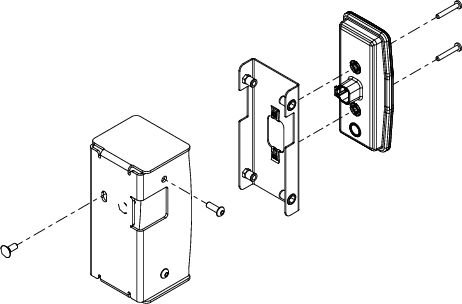

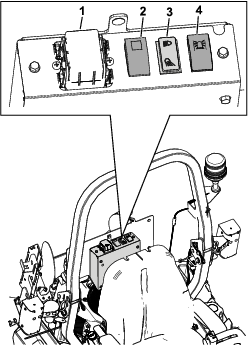

In the fuse box for the light-kit control panel, replace

the horn fuse (10 A) with the retained fuse (5 A). Ensure that the

control panel fuse box remains open.

-

Install the fuse box to the control panel with 2 screws

(M6 x 16 mm). Close the fuse box cover.

-

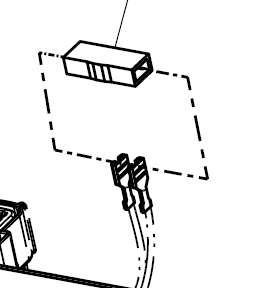

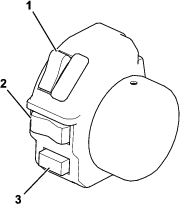

In the control panel, connect each switch, flasher

unit, and license plate light.