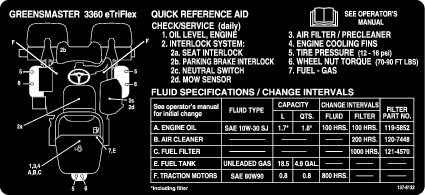

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

This machine is a ride-on, reel-blade mower intended to be used by professional, hired operators in commercial applications. It is designed primarily for cutting grass on well-maintained turf. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

When operated in autonomous mode, this robotic reel-blade mower is intended to be used by professional, hired supervisors for autonomous turf care in commercial applications. It is designed primarily for cutting grass on well-maintained turf on properties that meet Toro requirements detailed in Autonomous Site Assessment Criteria. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

Visit www.Toro.com for more information, including safety tips, training materials, accessory information, help finding a dealer, or to register your product.

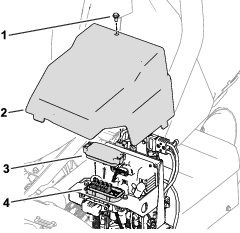

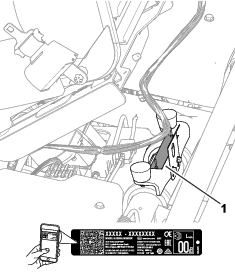

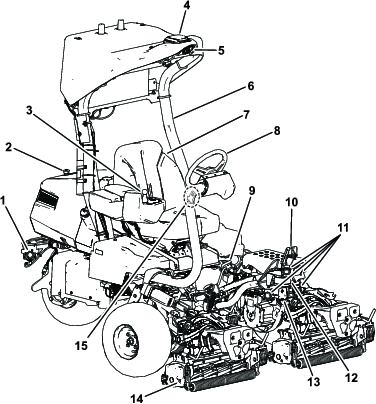

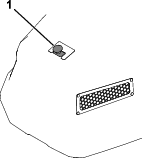

Whenever you need service, genuine Toro parts, or additional information, contact an authorized Toro distributor and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

Safety-Alert Symbol

The safety-alert symbol (Figure 2) shown in this manual and on the machine identifies important safety messages that you must follow to prevent accidents.

The safety-alert symbol appears above information that alerts you to unsafe actions or situations and is followed by the word DANGER, WARNING, or CAUTION.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

This manual uses two other words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

Modes of Operation

This machine is designed to perform two modes of operation:

-

Manual mode: Mode of machine operation in which the machine functions are controlled by an operator.

-

Autonomous mode: Mode of machine operation in which a machine performs functions related to its defined tasks without operator interaction; instead, operation is monitored by a qualified supervisor.

Autonomous Site Assessment Criteria

Follow these guidelines for operating the machine(s) in autonomous mode at an acceptable site.

Definition of Terms

A direct path is a path that the machine(s) can follow without encountering obstructions while operating in autonomous mode.

An obstruction prevents the machine(s) from continually operating in autonomous mode. The object detection system is designed to stop the machine when it detects any of the following obstructions:

-

Fences (e.g., solid wall or chain link fence; rope and temporary fences are not adequate obstructions)

-

Retaining walls

-

Continuous rows of hedges or vegetation taller than 1 m (3.3 ft) or with no gaps larger than the width of the machine

-

Ditches

-

Streams

-

Lakes

-

Buildings

-

Slopes too steep for the machine(s) to traverse

-

Any other impassable terrain that the machine can not physically traverse

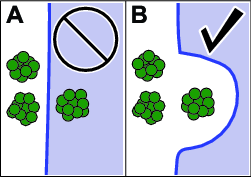

An autonomous operating area (AOA) is a supervisor-defined area where the machine(s) can follow a direct path while in autonomous mode.

A non-operating area (NOA) is a supervisor-defined area where the machine(s) is not allowed to follow a direct path while in autonomous mode.

An acceptable site meets all the criteria of the Autonomous Operating Area Site Safety Criteria.

Autonomous Operating Area Site Safety Criteria

Before enabling the machine to operate in autonomous mode, ensure that the boundary of the AOA is set at least 10 m (33 ft) away from any of the following hazards:

Note: Alternatively, if there is an obstruction (e. g., a solid wall or impassible terrain) between the machine and any of the following hazards, ensure that the boundary of the AOA is set at least 2 m (7 ft) away from the obstruction.

Public Roads

A public road is a road on which vehicles (e.g., automobiles, all-terrain vehicles, and bicycles) are allowed, but not pedestrians.

If public areas or trails are closed to the public during autonomous operations, the AOA boundary restrictions defined above do not apply.

Public Bicycle Trails

A public bicycle trail is a trail for daily, anytime use by the general public that allows the use of light two-wheeled vehicles (e.g., bicycles and scooters).

If public areas or trails are closed to the public during autonomous operations, the AOA boundary restrictions defined above do not apply.

Public Pedestrian Trails

A public pedestrian trail is a public path used by the general public which does not allow the use of vehicles.

If public areas or trails are closed to the public during autonomous operations, the AOA boundary restrictions defined above do not apply.

Deep Bunkers and Drop-Offs

A deep bunker or drop-off is a sand pit or depression that is 1.5 m (5 ft) or greater in depth within 1.0 m (39 inches) from the edge of the pit.

Maintenance Facilities

A maintenance facility includes the buildings and related outdoor areas used only by site personnel for maintaining and storing equipment, including the machine(s). The general public and other site personnel that are not maintaining equipment do not have access to the maintenance facility or related outdoor areas.

Private Property

Private property is any area that you do not have permission to access.

Slopes

Important: Excessive slopes can be included inside an AOA or less than 10 m (33 ft) away from an AOA boundary, but there must be an NOA boundary around them.

Measure the slope angles using a 1.25 m (4 ft) long piece of wooden board over the steepest part of the slope and placing an inclinometer on the board.

Do not allow machine(s) to operate in autonomous mode on excessive slopes as defined here;

-

Do not operate the machine on slopes greater than or equal to 14° (25% grade) for a horizontal distance greater than 10 m (33 ft).

-

Do not operate the machine on a slope greater than 15° (27% grade).

User Definitions

Qualified machine supervisor (Supervisor)

One or more individuals having the responsibility of overseeing the operation of the machine(s). A supervisor will have demonstrated:

-

Adequate machine control

-

A general understanding of the energy, powertrain, and control systems of the machine(s)

-

Been trained and read and understood the machine operator's manuals

Qualified manual operator (Operator)

One or more customer employees having the responsibility of manually driving the machine while it is in manual mode.

On-product emergency stop

An emergency-stop switch (e-stop) that is located on and attached to the machine. The switch functions only when the machine is in autonomous mode.

Mobile device

A supervisor’s mobile device (e.g., smart phone or tablet) that connects to the machine for programming, controlling, and monitoring the machine while it operates in autonomous mode. The device serves as the remote stop device that the supervisor must carry for stopping all functions of the machine(s) on command when necessary.

Terminology

Advisory—a message that informs the user of an operator error or anything that may cause a job to pause or halt and may require the user to intervene.

App—an abbreviation for software application. A computer program on a mobile device that performs one or more tasks. Also called application, mobile app, or web app.

Autonomous control system (ACS)—a system made up of software and hardware that enables a machine to perform tasks without human intervention for long periods of time.

Autonomous mode—a mode of machine operation in which a machine performs functions related to its defined tasks without operator interaction. Contrasts with manual mode.

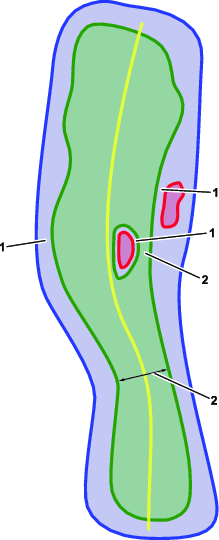

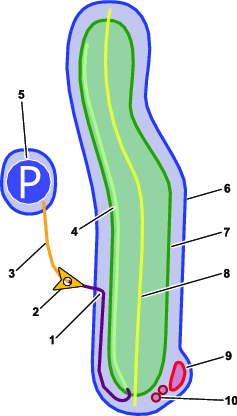

Autonomous operating area (AOA)—area in which autonomous operation is allowed. Within this area, the machine may freely decide which trajectories to execute when going from one place to another. This is typically an area with low number of fixed obstacles. In a golf course setting, this area has at least part of a fairway or a pick-up point within it.

Base station—in the context of external land surveying, it is a GNSS receiver at an accurately known, fixed location used to derive correction information for nearby portable GNSS receivers. See also Global Positioning System; GNSS receiver.

Boundary—something that indicates or fixes a limit or extent. For a robot, it is the outside, no-cross line of an operating area, path, or exclusion area. Also called perimeter. See also Operating Area; Path; Exclusion Area.

Centerline—a line that extends down the middle of the entire fairway. For tuxedo-style mowing patterns, the machine follows the curvature of this line while mowing.

Contiguous mowing area (CMA)—area in which mowing operation is performed. It is represented on the map by the lighter green line inside an AOA. This defines the area that will be mowed by the machine. A CMA may have holes within it but it is a single closed area and must be fully within a single AOA. In a golf course, this typically corresponds to a fairway or a fairway portion in case of fairways that are split in multiple parts by natural hazards (e.g., a lake).

Direction of Play (D.o.P)—in golf terms, the direction of play is the direction from tee to green. During autonomous mowing, the direction of play can be used when creating custom mowing patterns. The machine can mow with or against the direction of play, or it can be programmed to mow at an angle from the direction of play.

Exclusion area—an area recorded by the operator that the robot shall not enter. See Non-operational area (NOA).

Fault—the result of a mechanical, sensor, or software error, which requires service or correction of the machine, sensor, or software code.

Global navigation satellite system (GNSS)—a general term describing the global set of constellations used for satellite localization. See also Global Positioning System.

Global positioning system (GPS)—a U.S.-based, satellite constellation-based navigation system that uses a digital signal from each satellite to send data to a receiver. This receiver can then determine its approximate distance to the satellite, as well as the geographic position (GP) of the satellite, which is the location on the earth directly below the satellite.

GNSS antenna—a device used for receiving and expanding radio signals sent by distinct frequencies coming from GNSS satellites. See also Global Navigation Satellite System; Global Positioning System.

GNSS receiver—a device that can receive information from GNSS satellites. Also called satellite navigation device. See also Global Navigation Satellite System.

Go to pick-up point—a behavior that consists of the machine autonomously returning to a predefined point when requested by the supervisor.

Hole—a type of recorded area by the operator inside of a CMA that the robot can traverse but shall not mow. Record an NOA within the Hole if the machine should never enter an area while operating autonomously; see Non-operating area (NOA).

Inter-AOA paths—paths that the machine may take to travel between AOAs. These are represented in the map by orange lines. These defined paths typically correspond to paths that human-driven machines already use. The machine will follow these paths exactly or very closely when traveling between AOAs.

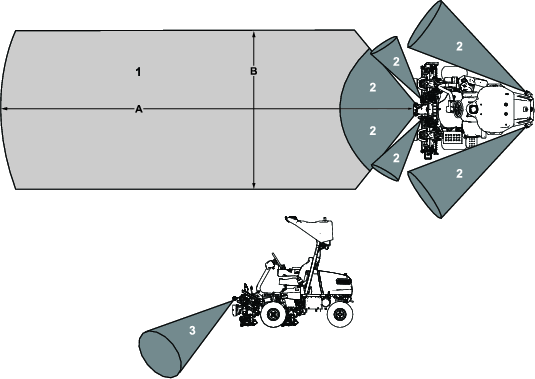

LiDAR (laser imaging, detection, and ranging)—see Sensor types.

Localization—the process of determining where a mobile robot is with respect to a global reference frame. Localization is a most fundamental competency required by robot as the knowledge of its location is necessary for making decisions about future actions.

Manual mode—a mode of machine operation in which machine functions are controlled by an operator. Contrasts with autonomous mode.

Mapping—the procedure of collecting the location and shape of relevant features in the environment, storing them with precision in a global reference frame.

Mission—a set of tasks to be performed by the machine.

Navigation—the ability of a robot to determine its own position in its frame of reference and plan a path toward some goal location.

Non-operating area (NOA)—area in which autonomous operation is forbidden. This type of area is used to indicate a natural obstacle or obstruction, an area within an AOA, or an area within a CMA in which the machine should never enter while operating autonomously (e.g., lakes, sand bunkers, or holes).

Object—an obstacle or a ground condition that can cause harm, or is harmed if it comes into contact or collision with the machinery. Objects are able to be seen by the machine’s object detection system; see Object detection.

Object detection—the process of detecting objects or terrain types that impede a robot’s motion.

Obstacle—a type of terrain feature or entity that could cause damage to or inhibit operation of the machine if it is not programmed to avoid this area.

Obstruction—a type of terrain feature or entity that is impassable by the machine. Examples of obstructions:

-

Fences

-

Buildings

-

Retaining walls

-

Bodies of water

-

Bunkers

-

Irrigation drainage holes

-

Raised grates

Parked mode—a mode of machine operation in which the autonomous/manual-mode switch is flipped to autonomous mode, but the ACS system is not ready or is turned off. Parked mode also results from an operator or an object in the environment interrupting autonomous operation of the machine and is forcing the machine to park itself while the issue is resolved.

Path—an autonomous, user-programmed route that a robot can travel on. During a mission with multiple fairways, the mower uses paths to travel autonomously between fairways. Also known as a Transit Path.

Perimeter—see Boundary.

Pick-up point—point inside an AOA where the operator leaves/picks up the machine before/after mowing or other operations. It is represented in the map by a blue P inside of a blue circle. The machine can return to this point if directed by the machine supervisor.

Pole—a defined point on the map that the machine treats as an NOA. These are mapped individually, and a set of Poles can be used to finely exclude areas the machine should avoid. It is useful for excluding areas that the machine should avoid without mapping a full NOA. See Non-operating area (NOA).

Proximity sensors—see Sensor types.

Radar—see Sensor types.

Real-time kinematics (RTK)—a real-time correction of geographic positioning (less than 3 cm or 1 inch under optimal conditions) using satellite messages to a stationary and precisely-located base station. RTK information is then typically communicated to the machine via a cellular connection to the Internet.

Satellite navigation device—see GNSS receiver.

Sensing—the feedback from the environment of the robot, which enables the robot to react to its environment. Sensory inputs may come from a variety of sensor types.

Sensor—a device that responds to physical stimuli (including, but not limited to, heat, light, sound, pressure, magnetism, and motion) and transmits the resulting signal or data providing a measurement, operating a control, or both. For example, a sensor can estimate the condition of a robot and its environment. This information is sent to a controller to enable the appropriate behavior. A robot requires extensive information about its environment to function effectively.

Sensor types—sensors provide input similar to human senses and can monitor other physical characteristics of the environment, turning this information into a digital form.

-

Position sensors—these sensors detect the position of an object. They can indicate the absolute position of the object (its location) or its relative position (displacement) in terms of linear travel, rotational angle, or three-dimensional space.

-

Proximity sensors—these sensors detect an object without contacting it.

-

Ultrasonic sensor

-

LiDAR

-

Radar

-

States—these are sets of properties of the machine and its status at a snapshot in time.

Supervisory app—see App.

Task—the building block of a mission. Tasks are chosen by the machine operator to be part of a given mission and represent a unit of work to be performed autonomously by the machine.

Ultrasonic—see Sensor types.

This product complies with all relevant European directives; for details, please see the separate product specific Declaration of Conformity (DOC) sheet.

It is a violation of California Public Resource Code Section 4442 or 4443 to use or operate the engine on any forest-covered, brush-covered, or grass-covered land unless the engine is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order or the engine is constructed, equipped, and maintained for the prevention of fire.

The enclosed engine owner's manual is supplied for information regarding the US Environmental Protection Agency (EPA) and the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through the engine manufacturer.

Operating this machine 1,000 m (3,280 ft) above sea level requires a high-altitude jet. Refer to your Kawasaki engine owner’s manual for more information.

|

Electromagnetic Compatibility Certification |

WarningThe Federal Communications Commission warns that changes or modifications of the radio module within this device not expressly approved by The Toro Company could void the user’s authority to operate the equipment. This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his expense. |

|

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including interference that may cause undesired operation of the device. |

|

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement. |

|

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum (or lesser) gain approved for the transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and its gain should be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for successful communication. |

|

This radio transmitter IC: 26511-RUT956AF has been approved by Industry Canada to operate with the antenna types listed below with the maximum permissible gain and required antenna impedance for each antenna type indicated. Antenna types not included in this list, having a gain greater than the maximum gain indicated for that type, are strictly prohibited for use with this device. |

|

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio peut fonctionner avec une antenne d'un type et d'un gain maximal (ou inférieur) approuvé pour l'émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à l'intention des autres utilisateurs, il faut choisir le type d'antenne et son gain de sorte que la puissance isotrope rayonnée équivalente (p.i.r.e.) ne dépasse pas l'intensité nécessaire à l'établissement d'une communication satisfaisante. |

|

Le présent émetteur radio IC: 26511-RUT956AFa été approuvé par Industrie Canada pour fonctionner avec les types d'antenne énumérés ci-dessous et ayant un gain admissible maximal et l'impédance requise pour chaque type d'antenne. Les types d'antenne non inclus dans cette liste, ou dont le gain est supérieur au gain maximal indiqué, sont strictement interdits pour l'exploitation de l'émetteur. |

|

Antenna: The Toro Company, Model 145-0335, TAOGLAS, TLS.01.1F11, Omnidirectional, Peak Gain 5.0 (dBi) |

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

General Safety

This product is capable of amputating hands and feet and of throwing objects.

-

Read and understand the contents of this Operator’s Manual before starting the engine.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Do not put your hands or feet near moving components of the machine.

-

Do not operate the machine without all guards and other safety protective devices in place and functioning properly on the machine.

-

Keep bystanders and children out of the operating area. Never allow children to operate the machine.

-

Unless you are preparing to operate the machine in autonomous mode, shut off the machine, remove the key, and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

Improperly using or maintaining this machine can result in injury.

To reduce the potential for injury, comply with these safety instructions

and always pay attention to the safety-alert symbol  , which means

Caution, Warning, or Danger—personal safety instruction. Failure

to comply with these instructions may result in personal injury or

death.

, which means

Caution, Warning, or Danger—personal safety instruction. Failure

to comply with these instructions may result in personal injury or

death.

General Safety – Autonomous Mode

Note: The autonomous mode safety is in addition to the general/manual mode safety.

-

The supervisor of the machine operating in autonomous mode is responsible for any accidents or hazards occurring to others or their property.

-

Read, understand, and follow all these instructions and warnings before enabling the machine to operate in autonomous mode.

-

Improperly using or maintaining the machine could result in serious injury or death. To reduce this potential, follow all safety instructions.

-

Do not allow children or untrained people to operate or service this machine. Allow only people who are responsible, trained, familiar with the instructions, and physically capable to operate or service the machine.

Before Operation Safety

General Safety

-

Never allow children or untrained people to operate or service the machine. Local regulations may restrict the age of the operator. The owner is responsible for training all operators and mechanics.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

Engage the parking brake, shut off the machine, remove the key, and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Know how to stop the machine and shut off the machine quickly.

-

Check that operator-presence controls, safety switches, and safety protective devices are attached and functioning properly. Do not operate the machine unless they are functioning properly.

-

Before mowing, always inspect the machine to ensure that the cutting units are in good working condition.

-

Inspect the area where you will use the machine and remove all objects that the machine could throw.

General Safety – Autonomous Mode

Note: The autonomous mode safety is in addition to the general/manual mode safety.

-

Inspect the area where you will use the machine and remove all foreign objects that the machine could throw.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

Know how to both stop the machine and prevent any parts from moving.

-

Do not operate the machine without all guards and other safety protective devices in place and working properly.

-

Keep bystanders and children out of the autonomous operating area. Never allow children to operate or supervise the machine. Only trained personnel should supervise this machine while it operates in autonomous mode.

-

Do not stand, sit, or ride on the machine or allow others to do so while the machine is operating in autonomous mode.

-

Regularly inspect the operating area for new hazards and address them before operating the machine.

-

If the machine rolls over, stay away from moving parts.

Fuel Safety

-

Use extreme care in handling fuel. It is flammable and its vapors are explosive.

-

Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

-

Use only an approved fuel container.

-

Do not remove the fuel cap or fill the fuel tank while the engine is running or hot.

-

Do not add or drain fuel in an enclosed space.

-

Do not store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or other appliance.

-

If you spill fuel, do not attempt to start the engine; avoid creating any source of ignition until the fuel vapors have dissipated.

During Operation Safety

General Safety

-

The owner/operator can prevent and is responsible for accidents that may cause personal injury or property damage.

-

Wear appropriate clothing, including eye protection; long pants; substantial, slip-resistant footwear; and hearing protection. Tie back long hair and do not wear loose clothing or loose jewelry.

-

Do not operate the machine while ill, tired, or under the influence of alcohol or drugs.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Before you start the engine, ensure that all drives are in neutral, the parking brake is engaged, and you are in the operating position.

-

Do not carry passengers on the machine.

-

Keep bystanders and children out of the operating area.

-

Operate the machine only in good visibility to avoid holes or hidden hazards.

-

Avoid mowing on wet grass. Reduced traction could cause the machine to slide.

-

Keep your hands and feet away from the cutting units.

-

Look behind and down before backing up to be sure of a clear path.

-

Use care when approaching blind corners, shrubs, trees, or other objects that may obscure your vision.

-

Stop the cutting units whenever you are not mowing.

-

Slow down and use caution when making turns and crossing roads and sidewalks with the machine. Always yield the right-of-way.

-

Operate the engine only in well-ventilated areas. Exhaust gases contain carbon monoxide, which is lethal if inhaled.

-

Do not leave a running machine unattended.

-

Unless you are preparing the machine to operate in autonomous mode, do the following before you leave the operating position:

-

Park the machine on a level surface.

-

Lower the cutting units to the ground and ensure that they are disengaged.

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

Wait for all movement to stop.

-

-

Operate the machine only in good visibility and appropriate weather conditions. Do not operate the machine when there is the risk of lightning.

Rollover Protection System (ROPS) Safety

-

Do not remove any of the ROPS components from the machine.

-

Ensure that the seat belt is attached and that you can release it quickly in an emergency.

-

Always wear your seat belt.

-

Check carefully for overhead obstructions and do not contact them.

-

Keep the ROPS in safe operating condition by thoroughly inspecting it periodically for damage and keeping all the mounting fasteners tight.

-

Replace all damaged ROPS components. Do not repair or alter them.

Slope Safety

-

Slopes are a major factor related to loss of control and rollover accidents, which can result in severe injury or death. You are responsible for safe slope operation. Operating the machine on any slope requires extra caution.

-

Evaluate the site conditions to determine if the slope is safe for machine operation, including surveying the site. Always use common sense and good judgment when performing this survey.

-

Review the slope instructions, listed below, for operating the machine on slopes. Before you operate the machine, review the site conditions to determine whether you can operate the machine in the conditions on that day and at that site. Changes in the terrain can result in a change in slope operation for the machine.

-

Avoid starting, stopping, or turning the machine on slopes. Avoid making sudden changes in speed or direction. Make turns slowly and gradually.

-

Do not operate a machine under any conditions where traction, steering, or stability is in question.

-

Remove or mark obstructions such as ditches, holes, ruts, bumps, rocks, or other hidden hazards. Tall grass can hide obstructions. Uneven terrain could overturn the machine.

-

Be aware that operating the machine on wet grass, across slopes, or downhill may cause the machine to lose traction. Loss of traction to the drive wheels may result in sliding and a loss of braking and steering.

-

Use extreme caution when operating the machine near drop-offs, ditches, embankments, water hazards, or other hazards. The machine could suddenly roll over if a wheel goes over the edge or the edge caves in. Establish a safety area between the machine and any hazard.

-

Identify hazards at the base of the slope. If there are hazards, mow the slope with a pedestrian-controlled machine.

-

If possible, keep the cutting units lowered to the ground while operating on slopes. Raising the cutting units while operating on slopes can cause the machine to become unstable.

-

Use extreme caution with grass-collection systems or other attachments. These can change the stability of the machine and cause a loss of control.

After Operation Safety

General Safety

-

Unless you are preparing the machine to operate in autonomous mode, engage the parking brake, shut off the engine, remove the key, and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Clean grass and debris from the cutting units and drives to help prevent fires. Clean up oil or fuel spills.

-

Shut off the fuel while storing or hauling the machine.

-

Disengage the drive to the attachment whenever you are hauling or not using the machine.

-

Allow the machine to cool before storing the machine in any enclosure.

-

Maintain and clean the seat belt(s) as necessary.

-

Do not store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or on other appliances.

Towing Safety

-

Tow only with a machine that has a hitch designed for towing. Do not attach towed equipment except at the hitch point.

-

Follow the manufacturer’s recommendation for weight limits for towed equipment and towing on slopes. On slopes, the weight of the towed equipment may cause loss of traction and loss of control.

-

Never allow children or others in or on towed equipment.

-

Travel slowly and allow extra distance to stop when towing.

Maintenance Safety

-

Before you leave the operator’s position, do the following:

-

Park the machine on a level surface.

-

Disengage the cutting unit(s).

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

Wait for all movement to stop.

-

-

Allow machine components to cool before performing maintenance.

-

If possible, do not perform maintenance while the engine is running. Keep away from moving parts.

-

Support the machine with jack stands whenever you work under the machine.

-

Carefully release pressure from components with stored energy.

-

Keep all parts of the machine in good working condition and all hardware tightened.

-

Replace all worn or damaged decals.

-

To ensure safe, optimal performance of the machine, use only genuine Toro replacement parts. Replacement parts made by other manufacturers could be dangerous, and such use could void the product warranty.

Maintenance Safety – Autonomous Mode

Note: The autonomous mode safety is in addition to the general/manual mode safety.

-

Do not modify the machine or software in any way.

-

Do not put anything on the machine.

-

Do not modify or override the machine controls or safety devices.

-

Improperly maintaining or using the machine could result in injury or death.

-

All maintenance procedures should be performed by a certified technician.

-

To ensure safe, optimal performance of the machine, use only genuine Toro replacement autonomous parts. Replacement autonomous parts made by other manufacturers could be dangerous.

Engine Safety

-

Shut off the engine before checking the oil or adding oil to the crankcase.

-

Do not change the governor speed or overspeed the engine.

Electrical System Safety

-

Disconnect the main-power connectors before repairing the machine.

-

Charge the battery in an open, well-ventilated area, away from sparks and flames. Unplug the charger before connecting or disconnecting the battery. Wear protective clothing and use insulated tools.

Storage Safety

-

Shut off the machine, remove the key, and wait for all movement to stop before you leave the operator’s position. Allow the machine to cool before adjusting, servicing, cleaning, or storing it.

-

Do not store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or other appliance.

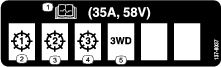

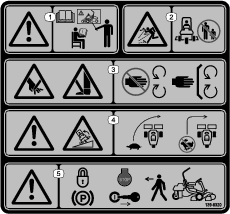

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Refer to Definition of Terms for descriptions of the modes listed in decal 145-0345.

Setup

Installing the Cutting Units

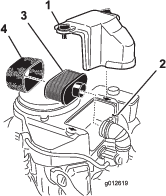

Parts needed for this procedure:

| Cutting unit (order separately; contact your authorized Toro distributor) | 3 |

| Electric counterweight | 3 |

| Capscrew | 6 |

| O-ring | 3 |

-

Prepare the cutting units for installation; refer to your cutting unit Operator’s Manual.

-

Apply grease to the inside spline of the drive coupler.

-

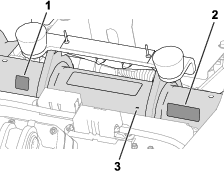

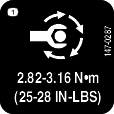

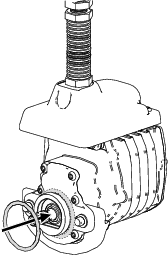

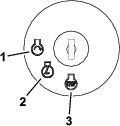

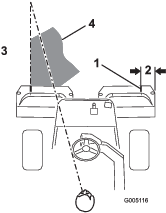

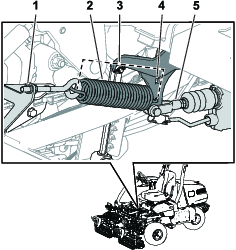

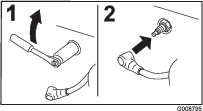

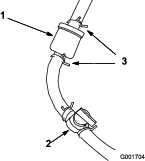

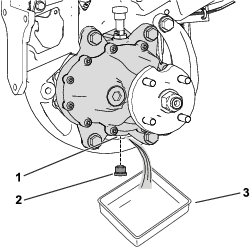

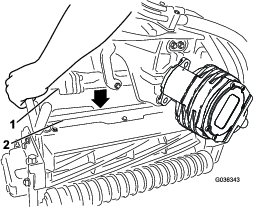

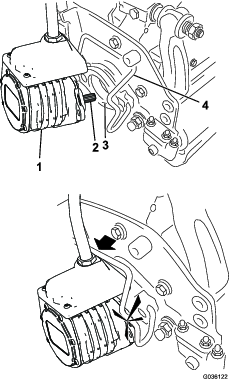

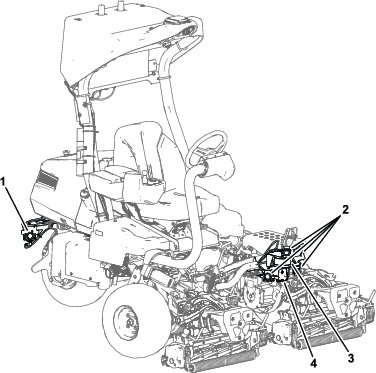

Install an O-ring to each reel motor as shown in Figure 3.

-

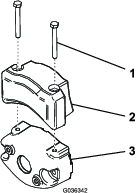

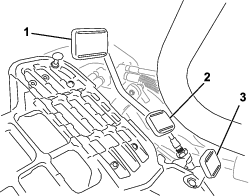

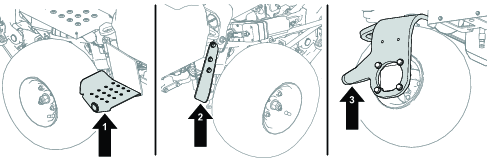

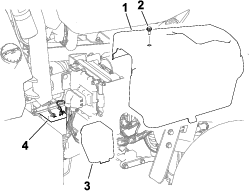

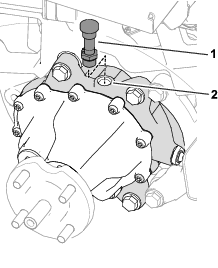

Secure the electrical counterweight to the existing counterweight with 2 capscrews as shown in Figure 4.

-

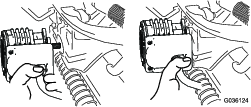

Install the cutting units; refer to Installing the Cutting Units.

Adjusting the Machine Settings

-

Connect the main-power connectors; refer to Main-Power Connectors.

-

Use the InfoCenter to adjust the machine settings; refer to Using the InfoCenter to Adjust the Machine Settings.

Installing the CE/UKCA Decals

Parts needed for this procedure:

| Production year decal | 1 |

| CE warning decal (Part Number 139-8321) | 1 |

| CE/UKCA decal (Part Number 138-9470) | 1 |

If you use this machine in a country that complies to CE/UKCA standards, install the following decals:

Reducing the Tire Pressure

The tires are overinflated at the factory for shipping purposes. Reduce the pressure to the proper levels before starting the machine; refer to Checking the Tire Pressure.

Adding the Machine as a myTurf

-

Verify that all users of the machine have myTurf credentials; refer to the myTurf Software Guide.

-

Within myTurf, add the machine as an Asset; refer to the myTurf Software Guide.

Activating or Renewing a Cellular Service or RTK Plan

-

Technicians that have access to Toro materials can find instructions for activating or renewing a cellular service or RTK plan on the GeoLink Service Center.

Note: Both are required in order to operate the machine autonomously.

-

Search for the “GeoLink Activation Process” service bulletin.

-

Follow and complete the steps within the service bulletin.

Wait for Toro to send the cellular and RTK credentials before proceeding.

-

Insert and rotate the key to the ON position.

-

Connect to the machine using the GeoLink Mow supervisory app.

-

From the top menu bar, select the SETTINGS button.

-

Under Local Reference Point, set the coordinates and height of a local reference point that the machine will use for GNSS RTK localization.

Note: Use decimal degrees for the coordinates and meters for the height.

-

Under NTRIP Corrections, enter the information for the NTRIP caster.

-

Under Credentials, enter the information for the RTK subscription.

Confirming Cellular and RTK Connectivity

Note: It is recommended to perform this test onsite at the course where the machine will operate. This will give an accurate idea of the strength of the signal to the machine during normal operation.

-

Insert and rotate the key to the ON position.

-

Drive the machine to an outdoors area.

-

Connect to the machine using the GeoLink Mow supervisory app.

-

From the top menu bar, select the DIAGNOSTICS button.

-

Under Mobile network, confirm that there is a cellular connection to the machine.

-

Under Localization, confirm that there is a RTK connection to the machine.

Note: It may take a few minutes for the machine to connect to a cellular network or an RTK base station.

Validating the Object Detection System

Validate that the sensors for the object detection system are functioning properly before activating autonomous mode; refer to Verifying the Object Detection System.

Verifying the Autonomous Control System (ACS)

-

Insert and rotate the key to the ON position.

-

Drive the machine to an outdoors area.

-

Hold the autonomous/manual-mode switch to the left for 2 seconds to activate autonomous mode; refer to Autonomous/Manual-Mode Switch.

-

Connect to the machine using the GeoLink Mow supervisory app.

-

From the top menu bar, select the DIAGNOSTICS button.

-

Select the diagnostic fields to open up the detailed drop-down menus. Ensure that the ACS is working correctly.

Validating the GNSS and IMU Systems

-

Inspect the roof line of the machine for any bent antennas.

-

Insert and rotate the key to the ON position.

-

Drive the machine to a mowing area.

-

Set up a test CMA; refer to Mapping the Autonomous Operating Area and Mapping the Contiguous Mowing Area.

-

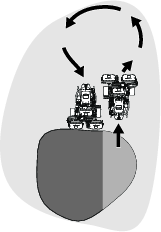

Create a mission for the mower to perform: for the first task, have it perform a clockwise cleanup pass on a fairway. Then, have it perform a counter-clockwise cleanup pass on the same fairway; refer to Creating a Mission and Creating a Custom Mowing Pattern

-

Run the mission; refer to Running a Mission.

-

Observe the machine during the mission and look for any inconsistent pathing between the clockwise and counter-clockwise passes.

Important: If differences are observed, it might be due to the antennas not being centered; contact technical support.

Product Overview

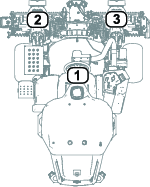

Key Switch

The key switch has 3 positions: OFF, ON, and START (Figure 9).

Use the key switch to start the engine, shut off the engine, or drive the machine without engine power; refer to Starting the Engine,Shutting Off the Engine, and Driving the Machine Without Engine Power.

Function-Control Switch

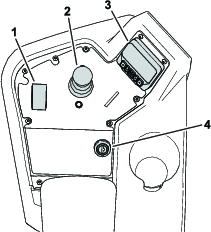

The function-control switch (Figure 8) provides 2 traction selections plus a NEUTRAL position.

-

NEUTRAL position—neutral and backlapping

-

MOW position—used for mowing operation

-

TRANSPORT position—used for transport operation

You can shift from MOW to TRANSPORT or TRANSPORT to MOW (not to NEUTRAL) while the machine is in motion; no damage will result

You can move the switch from TRANSPORT or MOW to NEUTRAL and the machine will come to a stop. If you try to switch from NEUTRAL to MOW or TRANSPORT while the pedal is not in the NEUTRAL position, an advisory occurs.

Lift/Lower Joystick

The lift/lower joystick (Figure 8) raises or lowers the cutting units. The joystick can engage or disengage the cutting-unit reels, depending on the function-control-switch position:

-

Function-control switch in the NEUTRAL position: The cutting units will raise or lower as long as you move the joystick forward or backward, but the reels will not engage unless the machine is in Backlap Mode.

-

Function-control switch in the MOW position: Move the joystick forward during your cutting operation to lower the cutting units and start the reels. Pull back on the joystick to stop the reels and raise the cutting units.

To stop the reels without raising the cutting units, pull back on the joystick momentarily and release it. Moving the joystick forward again will start the reels or pulling back again will lift the cutting units. You must engage this feature in the InfoCenter; refer to Adjusting the Tap-Off Delay.

-

Function-control switch in the TRANSPORT position: The cutting units can be raised, but the reels will not engage. An advisory appears in the InfoCenter if you attempt to lower the cutting units.

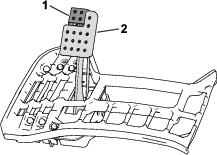

Traction Pedal

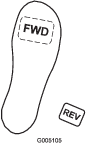

The traction pedal (Figure 10) has 3 functions: to make the machine move forward, to move it backward, and to stop the machine. Press the top of the pedal to move forward; press the bottom to move backward.

To stop the machine, allow the pedal to move to the NEUTRAL position. Do not rest the heel of your foot on the traction pedal in the REVERSE position while the machine is moving forward (Figure 11).

You can configure the maximum ground speed for manual mode operation as follows:

-

4.8 to 8 km/h (3 to 5 mph) forward mowing speed

-

8 to 16 km/h (5 to 10 mph) transport speed

-

3.2 to 8 km/h (2 to 5 mph) reverse speed

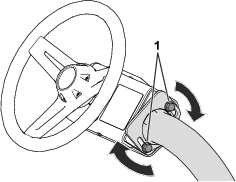

Steering-Arm-Locking Pedal

Press the pedal (Figure 10) and raise or lower the steering arm for operator comfort, then, release the pedal to lock the arm in place.

Brake Pedal

Press the brake pedal (Figure 12) to stop the machine.

Parking Brake

Use the parking brake (Figure 12) to prevent the machine from moving. To engage the parking brake, push down on the brake pedal and press the top forward to latch. To release the parking brake, press the brake pedal until the parking-brake latch retracts.

Autonomous Controls

Emergency-Stop (E-stop) Switch

In addition to the stop button in the supervisory app, another method of stopping the machine is to push down on the emergency-stop switch at the rear of the machine.

To disengage the emergency stop:

-

Pull the switch outward.

-

Reset the autonomous/manual-mode switch to enable autonomous mode.

Important: The E-stop switch only functions when the machine is operating in autonomous mode. Activating the E-stop switch does not affect a machine operating in manual mode.

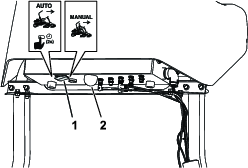

Autonomous/Manual-Mode Switch

Press and hold the autonomous/manual-mode switch to the left for 2 seconds to engage AUTONOMOUS mode.

Press the switch to the right to engage MANUAL mode.

The autonomous status light indicates the current autonomous state of the machine:

-

Solid white—ACS turned on and in manual mode

-

Solid green—executing autonomous mode; do not approach

-

Blinking green—in autonomous mode, but object is near

-

Solid red—safe to approach; machine parked

GeoLink Mow Supervisory App

The GeoLink Mow Supervisory App is the tool used for setting up and operating a machine for autonomous mowing.

| Menu Bar Item | Description |

| HOME | The HOME menu is the first screen in the web app, and has shortcuts to the DASHBOARD, MISSIONS, MAP, and SETTINGS menus, as well as the terms of use and legal notices. |

| DASHBOARD | The DASHBOARD menu lists the current machine statuses and mission statuses. The control buttons at the bottom of the screen also control the machine remotely. |

| MISSIONS | The MISSIONS menu has areas for creating new missions as well as viewing current missions and mission history. Create custom mowing patterns within this menu. |

| MAP |

The MAP menu displays a map of your property and any mapped fairways. It also contains controls for mapping operational areas and other autonomous features. While the machine is operating, it can be used to monitor the machine during a mission. |

| SETTINGS | The SETTINGS menu allows you to change RTK settings and credentials, general operating settings, and personal preferences for the machine. |

| HELP |

The HELP menu allows you to access map data, machine logs, the operator’s manual, performance data, and software version information. |

| DIAGNOSTICS |

The DIAGNOSTICS menu lists the statuses of various parts of the machine, including hardware, sensors, and localization and connectivity information. This information can be used to troubleshoot issues with the machine, as it can quickly tell you which machine controls are active, disabled, or experiencing issues. |

| LOGOUT |

Log out of your myTurf account. |

| Menu Item | Description | |

| Local Reference Point | ||

| LATITUDE | Set the latitude of a local reference point that the machine uses for GNSS RTK localization. Use decimal degrees format. | |

| LONGITUDE | Set the longitude of a local reference point that the machine uses for GNSS RTK localization. Use decimal degrees format. | |

| HEIGHT | Set the height (in meters) of a local reference point that the machine uses for GNSS RTK localization. | |

| NTRIP Corrections | ||

| HOSTNAME | Set the connection name URL for the NTRIP (RTK) caster. | |

| PORT NUMBER | Set the port number for the caster. | |

| MOUNT POINT | Set a mount point name for the outgoing GNSS data stream from the caster. | |

| NMEA GGA Message | ||

| REQUIRED | Enables or disables NMEA GGA messages. Required is enabled by default. | |

| UPDATE PERIOD | Set the frequency of NMEA GGA messages. 5 seconds is the default setting. | |

| Credentials | ||

| USERNAME | Enter the username for the RTK subscription. | |

| PASSWORD | Enter the password for the RTK subscription. | |

| Map | ||

| LOCK MAP | Removes the ability to modify, delete, or create new mapped areas. | |

| Mowing | ||

| OVERLAP | Set the amount of overlap during mowing passes. | |

| Machine Speeds | ||

| MAIN MOWING SPEED | Set the maximum allowable speed of the machine during mowing. | |

| PERIMETER MOWING SPEED | Set the maximum allowable speed of the machine during clean-up passes. | |

| TRANSPORT SPEED | Set the maximum allowable speed of the machine when not mowing. | |

| Machine Info | ||

| FRIENDLY NAME | Set a name for the machine. It will be used in messages sent to the supervisor’s phone. | |

| User Info | ||

| LANGUAGE | Set the user interface language. | |

| UNITS | Set the units of measurement for the app. | |

| RESET SETTINGS TO FACTORY | Select to return to default factory settings. | |

Note: After changing the settings, select Save to save your settings, then key cycle the machine in order to enable the settings.

| Menu Item |

| MOBILE NETWORK > CARRIER NAME |

| MOBILE NETWORK > CONNECTION TYPE |

| MOBILE NETWORK > SIGNAL QUALITY |

| LOCALIZATION > GNSS STATUS |

| LOCALIZATION > GNSS ACCURACY |

| LOCALIZATION > VALID SATELLITES |

| LOCALIZATION > ROVER SATELLITES |

| LOCALIZATION > BASE SATELLITES |

| LOCALIZATION > RTK CONNECTION |

| LOCALIZATION > LOCALIZATION ACCURACY |

| EMERGENCY STOP |

| SENSORS > LIDAR DISTANCE |

| SENSORS > SONAR FRONT LEFT |

| SENSORS > SONAR REAR LEFT |

| SENSORS > SONAR REAR RIGHT |

| SENSORS > SONAR FRONT RIGHT |

| SENSORS > SONAR TOP LEFT |

| SENSORS > SONAR TOP RIGHT |

| SENSORS > RADAR FIELD NEAR |

Note: The machine may stop if the SIGNAL QUALITY or RTK CONNECTION fields display BAD. The machine doesn’t have a strong enough connection to the cellular network or the RTK base station in order to operate.

| Menu Item | Description | |

| Machine Status | ||

| STATE | Displays the current state of the machine. Refer to Machine State for a list of machine states. | |

| GNSS | Displays the quality of the GNSS signal. 90% or greater is good; 60% or less is poor. Use the DIAGNOSTICS menu and the LOCALIZATION list to help diagnose issues with GNSS/localization. | |

| SPEED | Displays the current speed of the machine. | |

| Mission Status | ||

| STATE | Displays the state of the current mission, mission progress, and time remaining to complete the mission. Refer to Mission State for a list of mission states. If a mission is not selected, the list will be blank. | |

| MISSION | Displays the ID number for the selected mission. | |

| FAIRWAYS | Displays the fairways in the queue for the current mission as well as a progress bar for each fairway. | |

| PATTERN | Displays the mowing pattern for the current mission. This may take up to 10 seconds to load. | |

| PROGRESS | Displays the progress percentage for the current mission. This may take up to 10 seconds to load. | |

| TIME REMAINING | Displays the estimated time until the mission is completed. | |

| CONTINUE | Button appears 10 minutes before the machine is scheduled to mow the next fairway in the mission. A text message is sent to the supervisor’s mobile device with a link to the DASHBOARD. Select the button, read the approval agreement, and select Accept to allow the machine to continue to the next fairway. | |

—Machine States

Refer to the following table for the meaning of the machine state display:

| Display | Meaning | Solution (if applicable) |

| Unknown | Unknown error | Key cycle the machine. Note: This may take up to 5 minutes. |

| Setup | The setup is occurring. | Wait and stand clear of the machine. |

| Idle | The machine is set to IDLE. | Set the mode to either MANUAL or AUTO. |

| Manual mode | The machine is set to MANUAL mode. | |

| Setup | The machine is set up for AUTO. | Press Go and accept the notice. |

| Awaiting notice | The app is waiting for you to accept the notice. | Press Go and accept the notice. |

| Calibrating | The machine is initiating autonomous mode. | Wait for at least 3 minutes and stand clear of the machine. |

| On standby | The machine is in autonomous mode and idling. | Plan a mission and press Go. |

| Executing | The machine is currently executing a mission. | |

| Going to sidestop | The machine is parking itself on the side. | |

| Going to pickup | The machine is going to the pick-up point. | |

| Going to point | The machine is going to a point the operator has selected on the map. | |

| Parked | The machine is in PARKED mode. |

Note: If the solution is to wait, waiting 30 seconds should be sufficient for the state to progress to another state. If not, key cycle the machine.

—Mission States

Refer to the following table for the meaning of the mission state display:

| Display | Meaning | Solution (if applicable) |

| Error | Unknown error | Key cycle the machine. Note: This may take up to 5 minutes. |

| Setup | Setting up | Wait. |

| Initializing | Initializing | Wait. |

| Loading | Loading missions | Wait. |

| Preparing | Loading missions | Wait. |

| Idle | No mission selected | Plan a mission and press Go. |

| Mowing | Mowing | |

| Paused | The mission is paused. | Press Go to resume the mission. |

| Canceled | The mission was canceled. | Create a mission. |

| Completed | The mission was completed. | Plan a new mission and press Go. |

| Waiting |

Note: If the solution is to wait, wait 3 minutes to allow the state to progress to another state. If it does not progress, key cycle the machine.

—Remote Machine Controls

The DASHBOARD screen has buttons for controlling the machine during a mission.

—Advisories and Faults, History Log

Diagnostic messages appear whenever the machine is undergoing an important action or encounters a fault.

Note: Filter messages according to the level of severity by selecting a severity level using the buttons in the top right.

| Icon | Meaning |

Info  | Advisory information about important actions. |

Issue  | There is an issue with the machine, but the machine will continue to operate. |

Error  | There is an issue with the machine that stops it from operating. |

| Display | Meaning | Solution (if applicable) |

| Canceled mission ## | Mission has been canceled by the operator. | Plan a new mission and press Go. |

| Canceling mission ## | Mission is being canceled by the operator. | Plan a new mission and press Go. |

| Completed mission ## | Mission is complete. | Plan a new mission and press Go. |

| Error in mission ## | Mission encountered an error and the machine is unable to operate. |

|

| Executing mission ## | Mission is being executed. | |

| Initializing mission ## | Mission is about to start. | |

| Loading mission ## | Mission is loading mission details. | |

| Pause mission ## | Mission was paused by the operator. | |

| Arrived at side stop point | Machine has arrived to the side stop point as ordered by the operator. | |

| Arrived at pickup point | Machine has arrived to the pickup point as ordered by the operator. | |

| System started | Machine key is in the ON position and the ACS system starts up. | |

| Arrived at specified point | Machine has arrived to the specified point chosen by the operator. | |

| Unable to prepare mission | Machine encountered an error while processing mission details. | |

| Difficult start position. | Machine is in a difficult start position. | |

| Preparing execution of mission ## | Mission is being processed. | |

| Map is empty | All map data is missing from the database. |

Menu

| Menu Item | Definition |

| MAP DATA |

Download, export, and import map files used on the machine. Export maps to other machines in a fleet, or, in order to reduce turf scrubbing, import additional maps with different transit paths to the machine; see Saving and Exporting Map Data. |

| LOGS |

Use this section to download logs from the machine. There are options to download complete logs or only the latest log report. You may also log a specific timeframe by using the Full Sample Logging controls. Note: It is not recommended to download these files while on a cellular connection since the files are large. |

| MANUAL |

Select this link to view the online Operator’s Manual. |

| ACS PERFORMANCE COUNTERS |

View data related to the performance and history of the autonomous machine. |

| SOFTWARE INFORMATION |

View software versions for the different autonomous systems. |

InfoCenter

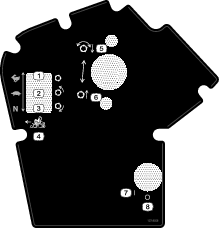

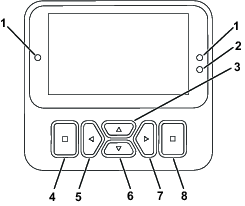

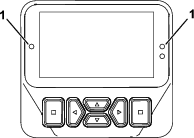

Using the InfoCenter Display

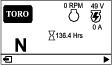

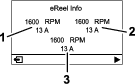

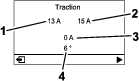

The InfoCenter display (Figure 16) shows information about your machine, such as the operating status, various diagnostics, and other information about the machine.

Note: The purpose of each button may change depending on what is required at the time. Each button is labeled with an icon displaying its current function.

Use the navigational buttons to navigate between several screens and menu items:

-

Splash screen: shows current machine information for a few seconds after you move the key to the ON position.

-

Main information screen (Figure 17): shows current machine information while the key is in the ON position.

-

eReel motor screen (Figure 18): shows the speed and current of each cutting-unit motor.

-

Traction motor screen (Figure 19): shows the current steering angle and the amperage allotted to each traction motor.

-

Main menu: refer to Understanding the InfoCenter Menu Items.

| Hour meter |

| Function-control switch is in the NEUTRAL position. |

| Function-control switch is in the TRANSPORT position. |

| Function-control switch is in the MOW position. |

| The operator must sit in the seat when in manual mode. |

| The parking brake is engaged. |

| The electric parking brake is engaged. |

| Start the engine. |

| Engine |

| The PTO is on. |

| The PTO is disengaged. |

| Battery |

| Indicates when the cutting units are being raised. |

| Indicates when the cutting units are being lowered. |

| Active |

| Inactive |

| Previous |

| Next |

| Increase |

| Decrease |

| Previous screen |

| Next screen |

| Increase value |

| Decrease value |

| Menu |

| Scroll up/down |

| Scroll left/right |

Understanding the InfoCenter Menu Items

To access the main menu, press the back/exit button while at any of the information screens.

Refer to the following tables for a description of the options available from the menus:

| Menu Item | Description |

| FAULTS | The FAULTS menu contains a list of the recent machine faults. Refer to the Service Manual or your authorized Toro distributor for more information on the FAULTS menu. |

| SERVICE | The SERVICE menu contains information on the machine such as hours of use, counts, and calibration. You can also enable the cutting-unit backlap procedure. Refer to the Service table. |

| DIAGNOSTICS | The DIAGNOSTICS menu lists various states and data that the machine currently has. You can use this information to troubleshoot certain issues, as it quickly tells you which machine controls are on/off and lists control levels (e.g., sensor values). Refer to the Diagnostics table. |

| SETTINGS | The SETTINGS menu allows you to modify settings for the InfoCenter display. Refer to the Settings table. |

| MACHINE SETTINGS | The MACHINE SETTINGS menu allows you to adjust machine settings, such as reel speed, maximum mowing speed, and maximum transport speed. Refer to the Machine Settings table. |

| ABOUT | The ABOUT menu lists the model number, serial number, and software version of your machine. Refer to the About table. |

AUTONOMOUS | The AUTONOMOUS menu lists settings for testing the autonomous operation of the machine. |

| Menu Item | Description |

| HOURS | Lists the total number of hours that the key, engine, reels, and backlap have been on, as well as the next service due. |

| COUNTS | Lists the number of starts, mows, tap-offs, backlaps, and number of times that the engine was cranked longer than 30 seconds. |

| BACKLAP | Engages/disengages the cutting-unit backlap procedure (when you engage this procedure, you can disengage the mode with this setting or by moving the key to the OFF position). |

CALIBRATION  | Allows you to calibrate the steering system, traction system, and lift actuators. Refer to the Service Manual for more information on calibration. |

| Menu Item | Description |

| ENGINE | Indicates the inputs and outputs for starting the engine. |

| 48V ENABLE | Indicates the inputs and outputs for the 48V system. |

| GENERATOR | Indicates the inputs and outputs for the generator. |

| TRACTION | Indicates the inputs and outputs for the traction pedal. |

| STEERING | Indicates the inputs and outputs for the steering system. |

| LIFT/LOWER | Indicates the inputs and outputs for raising and lowering the cutting units. |

| PTO | Indicates the inputs and outputs for enabling the PTO circuit. |

CAN STATISTICS | Indicates the inputs and outputs for the CAN. |

| 12V SYSTEM | Indicates the inputs and outputs for the 12V system. |

| AUTONOMOUS | Indicates the inputs and outputs for the autonomous system. |

| Menu Item | Description |

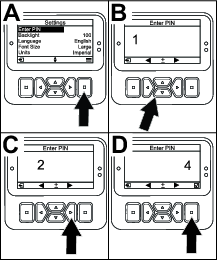

| ENTER PIN | Allows a person (superintendent/mechanic) authorized by your company with the PIN code to access protected menus. |

| BACKLIGHT | Controls the brightness of the LCD display. |

| LANGUAGE | Controls the language used on the InfoCenter. |

| FONT SIZE | Controls the size of the font on the InfoCenter. |

| UNITS | Controls the units used on the InfoCenter. The menu choices are English or metric. |

PROTECT SETTINGS  | Controls the protected menus. |

RESET DEFAULTS | Resets the InfoCenter to default settings. |

| Menu Item | Description |

TAPOFF TIME  | Controls the tap-off delay. |

REEL SPEED  | Controls the blade speed on the cutting units. |

LOWER SPEED | Sets the speed that the cutting units lower to the ground for mowing. |

BACKLAP SPEED  | Controls the backlap speed. |

CLIP CONTROL  | Turns the automatic clip-control feature on or off.. |

BLADE COUNT  | Set the number of blades in each reel. This setting is only necessary if CLIP CONTROL is set to ON. |

HEIGHT OF CUT | Sets the desired height of cut. This setting is only necessary if CLIP CONTROL is set to ON. |

MAX MOW  | Sets the maximum machine speed while mowing. |

MAX TRANSPORT  | Sets the maximum machine speed while transporting. |

MAX REVERSE  | Sets the maximum machine speed while moving the machine in reverse. |

SLOW & TURN  | Enables or disables the slow in turn function. |

3WD KIT  | Enables or disables the 3-Wheel Drive Kit. |

| Menu Item | Description |

| MODEL | Lists the model number of the machine. |

| SN | Lists the serial number of the machine. |

| S/W REV | Lists the software revision of the master controller. |

| S/W Rev ACS | Lists the software revision of the ACS. |

XDM-2700  | Lists the software revision of the InfoCenter. |

CUTTING UNIT 1 | Lists the software revision of the center cutting unit motor. |

CUTTING UNIT 2 | Lists the software revision of the front, left cutting unit motor. |

CUTTING UNIT 3 | List the software revision of the front, right cutting unit motor. |

GENERATOR | Lists the serial number of the generator. |

LIFT LOWER 1 | Lists the software part number and the revision version for the center cutting unit. |

LIFT LOWER 2 | Lists the software part number and the revision version for the front left cutting unit. |

LIFT LOWER 3 | Lists the software part number and the revision version for the front right cutting unit. |

TRACTION1 | Lists the software part number and the revision version for the front right traction motor. |

TRACTION2 | Lists the software part number and the revision version for the front left traction motor. |

TRACTION3 | Lists the software part number and the revision version for the 3-Wheel Drive Kit (if equipped). |

STEERING | Lists the software part number and the revision version for the rear steering motor. |

| Menu Item | Description |

| EMULATE MOWING | Autonomous behavior is followed, but the cutting units will not be engaged. |

| OVERRIDE ACS LOWER | Autonomous behavior is followed, but the cutting units will lower only to the extent allowed by LOWER LIMIT. |

| LOWER LIMIT | A percentage of the lower position commanded by the ACS. 85 is enough to observe that the cutting units will lower, but they will not hit the ground. |

Note:  Protected

under Protected Menus—accessible only by entering PIN; refer

to Accessing Protected Menus.

Protected

under Protected Menus—accessible only by entering PIN; refer

to Accessing Protected Menus.

Accessing Protected Menus

Note: The factory default PIN code for you machine is either 0000 or 1234.If you changed the PIN code and forgot the code, contact your authorized Toro distributor for assistance.

-

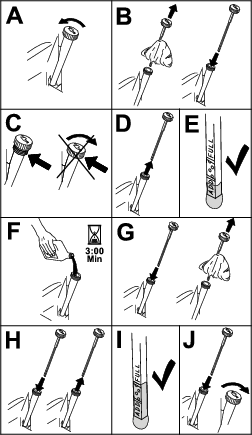

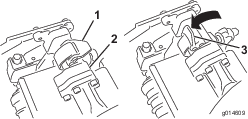

From the MAIN MENU, scroll down to the SETTINGS menu and press the select button (Figure 20).

-

In the SETTINGS menu, scroll to ENTER PIN and press the select button (Figure 21A).

-

To enter the PIN code, press the up/down navigation buttons until the correct first digit appears, then press the right navigation button to move on to the next digit (Figure 21B and Figure 21C). Repeat this step until the last digit is entered.

-

Press the select button (Figure 21D).

Note: If the display accepts the PIN code and the protected menu is unlocked,

displays in the upper right corner of the screen.

displays in the upper right corner of the screen. -

To lock the protected menu, rotate the key switch to the OFF position and then to the ON position.

Viewing and Changing the Protected Menu Settings

-

In SETTINGS, scroll down to PROTECT SETTINGS.

-

To view and change the settings without entering a PIN code, use the select button to change the PROTECT SETTINGS to

(Off).

(Off). -

To view and change the settings with a PIN code, use the select button to change the PROTECT SETTINGS to

(On),

set the PIN code, and turn the key in the ignition switch to the OFF position and then to the ON position.

(On),

set the PIN code, and turn the key in the ignition switch to the OFF position and then to the ON position.

Understanding the Diagnostic Light

-

Flashing red—active fault

-

Solid red—active advisory

-

Solid blue—calibration/dialog messages

-

Solid green—normal operation

Standard Display Messages When Machine is not in Manual Mode

The #1 LEDs turn solid blue and the following messages may display when the machine is not in manual mode. Wait or follow the instructions on the display to operate the machine:

-

MACHINE NOT READY FOR AUTONOMOUS

-

ACS NOT READY, PLEASE WAIT

-

HOLD AUTONOMOUS ENGAGE FOR 2 SECONDS

-

AUTONOMOUS ACTIVE, LEAVE MACHINE AND USE THE APP

Advisories

Operator advisories automatically display on the InfoCenter screen or the supervisory app when a machine function requires additional action. For example, if you attempt to start the engine while pressing the traction pedal, an advisory displays, indicating that the traction pedal must be in the NEUTRAL position.

For each advisory that occurs, there is an advisory code (letter and number), an issue (first line of the message e.g., autonomous denied, autonomous abort), a cause (the cause of the advisory displayed), and a remedy (second line of text).

Note: Advisories are not recorded into the fault log.

Refer to the following table for all of the InfoCenter advisories:

Note: You can clear an advisory from the InfoCenter display screen by pressing any of the keys.

| Code | Issue | Cause | Remedy |

| B2900 | Autonomous Denied | Parking brake engaged | Disengage parking brake |

| B2901 | Autonomous Denied | Not in MOW | Move the function-control switch to MOW |

| B2902 | Autonomous Denied | An operator is in the seat | Leave the operator’s seat |

| B2903 | Autonomous Denied | The traction pedal is engaged | Return the traction pedal to the NEUTRAL position |

| B2904 | Autonomous Denied | Joystick switch engaged | Disengage joystick switch |

| B2905 | Autonomous Denied | There is steering wheel movement | Stop moving the steering wheel |

| B2906 | Autonomous Denied | Machine is not ready | Wait or address fault |

| B2907 | Autonomous Denied | ACS is not ready | Wait or address fault |

| B2908 | Autonomous Denied | Various | Consult the supervisory app |

| B2910 | Autonomous Abort | Operator aborted | Reset the autonomous/manual-mode switch |

| B2911 | Autonomous Abort | Fault(s) active | Machine service required. Resolve active fault(s) |

| B2912 | Autonomous Abort | Operator presence detected | Reset the autonomous/manual-mode switch |

| B2913 | Autonomous Abort | Object detected | Reset the autonomous/manual-mode switch |

| B2914 | Autonomous Abort | Various | Consult the supervisory app |

| B2940 | Autonomous Degraded | Various | Consult the supervisory app |

| B2950 | Autonomous Paused | Various | Consult the supervisory app |

Refer to the following table for all of the supervisory app advisories:

| Code | Issue | Cause | Remedy |

| B2908-1 | Autonomous operation denied | Machine is outside an AOA | Move the machine to an AOA |

| B2908-2 | Autonomous operation denied | Map is not valid |

|

| B2914-1 | Autonomous operation aborted | Maximum slope allowed was exceeded |

|

| B2914-2 | Autonomous operation aborted | Machine exited autonomous operation |

|

| B2914-3 | Autonomous operation aborted | IMU not healthy; unable to operate |

|

| B2914-4 | Autonomous operation aborted | Emergency Stop was triggered | Release the Emergency Stop button and reset autonomous operation |

| B2914-5 | Autonomous operation aborted | Sonar Front Left was triggered |

|

| B2914-6 | Autonomous operation aborted | Sonar Rear Left was triggered |

|

| B2914-7 | Autonomous operation aborted | Sonar Rear Right was triggered |

|

| B2914-8 | Autonomous operation aborted | Sonar Front Right was triggered |

|

| B2914-9 | Autonomous operation aborted | Radar field near was triggered |

|

| B2914-10 | Autonomous operation aborted | Sonar Top Left was triggered |

|

| B2914-11 | Autonomous operation aborted | Sonar Top Right was triggered |

|

| B2914-12 | Autonomous operation aborted | Autonomous/manual-mode switch is in manual mode |

Reset the autonomous/manual-mode switch |

| B2940-1 | Autonomous operation performance degraded | An obstacle near the machine is affecting operation |

|

| B2940-2 | Autonomous operation performance degraded | PC temperature is outside of operational limits | Performance may be degraded but the machine is fully operationalIf the problem persists, contact technical support |

| B2940-3 | Autonomous operation performance degraded | Wheels are slipping |

|

| B2940-4 | Autonomous operation performance degraded | IMU error is outside of operational limits | Performance may be degraded but the machine is fully operationalIf the problem persists, contact technical support |

| B2940-5 | Autonomous operation performance degraded | Distance to base station is outside of operational limits | Performance may be degraded but machine is fully operational |

| B2940-6 | Autonomous operation performance degraded | No connection to mobile network |

|

| B2940-7 | Autonomous operation performance degraded | LiDAR temperature is outside of operational limits |

|

| B2950-1 | Autonomous operation paused | Distance from current position to the last position of the machine is outside of operational limits |

|

| B2950-2 | Autonomous operation paused | Navigation error |

|

| B2950-3 | Autonomous operation paused | PC response time is outside of operational limits | Performance may be degraded but the machine is fully operationalIf the problem persists, contact technical support |

| B2950-4 | Autonomous operation paused | Base station signal quality is outside of operational limits |

|

| B2950-5 | Autonomous operation paused | Poor GNSS RTK quality |

|

| B2950-6 | Autonomous operation paused | Machine is connected to a base station different from the one used while mapping |

|

| B2950-7 | Autonomous operation paused | Position accuracy outside of operational limits |

|

| B2950-8 | Autonomous operation paused | Lift/Lower subsystem has a problem |

|

| B2950-9 | Autonomous operation paused | PTO subsystem has a problem |

|

| B2950-10 | Autonomous operation paused | Steering subsystem has a problem |

|

| B2950-11 | Autonomous operation paused | Traction subsystem has a problem |

|

| B2950-12 | Autonomous operation paused | Mission encountered an error while processing mission details |

|

| B2950-13 | Autonomous operation paused | Difficult start position |

Move the machine to an open area in order to speed up operation |

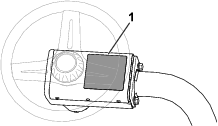

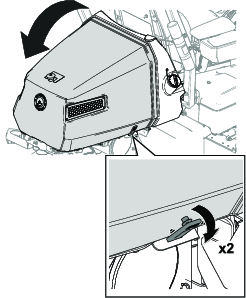

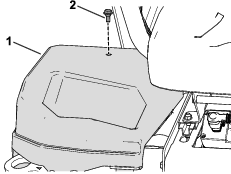

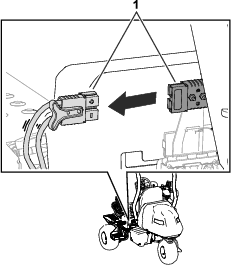

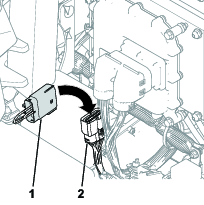

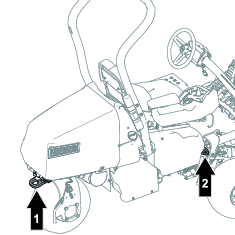

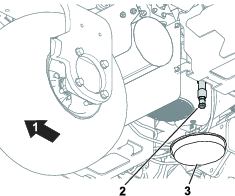

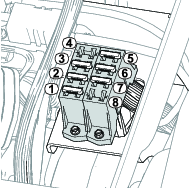

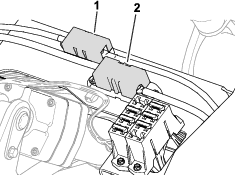

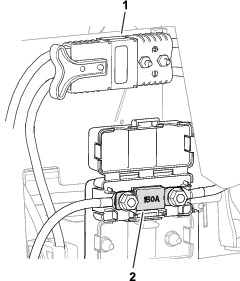

Main-Power Connectors

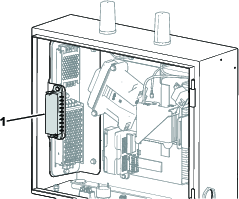

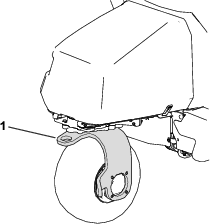

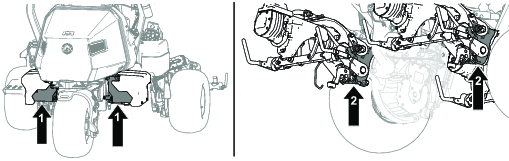

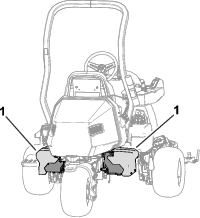

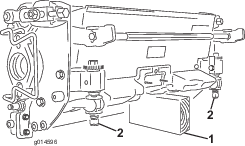

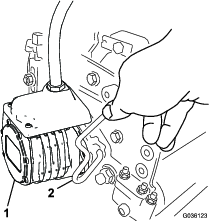

Before working on the machine or installing, removing, or working on the cutting units, disconnect the machine from the power supply by separating the main-power connectors (Figure 23), located at the base of the rollover bar on the left side of the traction unit. Plug the connectors together before operating the machine.

Caution

If you do not disconnect the power to the machine, someone could accidentally start the machine, causing serious bodily injury.

Always separate the connectors before working on the machine.

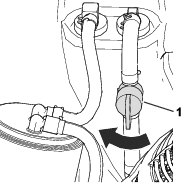

Fuel-Shutoff Valve

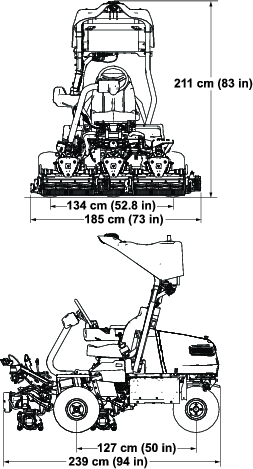

Refer to Figure 25 and the Specifications Table for dimensions and weight.

Note: Specifications and design are subject to change without notice.

| Width of cut | 151 cm (59.5 inches) |

| Wheel track | 134 cm (52.8 inches) |

| Wheel base | 127 cm (50 inches) |

| Overall length | 239 cm (94 inches) |

| Overall width | 185 cm (73 inches) |

| Overall height | 211 cm (83 inches) |

| Weight* | 841 kg (1,855 lb) |

| *Traction unit equipped with 8-blade cutting units, no fuel, no operator, and with the Standard Seat equipped. | |

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or authorized Toro distributor or go to www.Toro.com or a list of all approved attachments and accessories.

To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Operation

Before Operation

Supervisor Information

Supervisor for Deployment and Operation of Machine(s)

-

The supervisor is responsible for inspecting the machine(s) prior to use to ensure that it is ready to operate reliably. Inspections include but are not limited to the following:

-

Verify that the sensors are functioning properly, clean of dust and debris, and are pointed in the proper direction prior to daily deployment.

-

Perform normal daily operation checklist(s) as required for the machine(s) prior to daily deployment. Acceptance is in the app.

-

The machine does not operate autonomously until the supervisor accepts the criteria listed in the supervisory app agreement.

-

Perform any additional maintenance or readiness checks as detailed in the training or instructions provided by the machine(s).

-

Carry the mobile device connected to the machine via the autonomous control app at all times.

-

-