Introduction

Intended Use

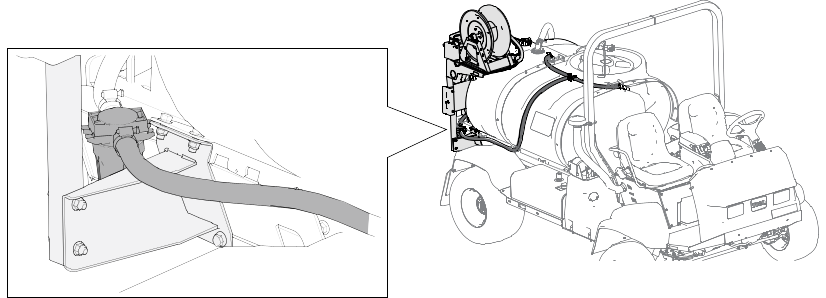

This kit is designed to remove

residual chemicals from a sprayer tank and affected hoses. It is a

dedicated attachment for a turf spray application

vehicle and is intended to be used by professional, hired operators

in commercial applications.

The information in this manual

can help you and others avoid injury and product damage.

Getting Help

g014295s

Visit www.Toro.com for product

safety and operation training materials, accessory information, help

finding a dealer, or to register your product.

Whenever you

need service, genuine Toro parts, or additional information,

contact an Authorized Service Dealer or Toro Customer Service and have the

model and serial numbers of your product ready. These numbers are

located on the serial plate on your product  . Write the numbers in the space

provided.

. Write the numbers in the space

provided.

. Write the numbers in the space

provided.

. Write the numbers in the space

provided.| Important |

With your mobile device, you can

scan the QR code on the serial number decal (if equipped) to access

warranty, parts, and other product information.

| Model Number: |

Serial Number: |

Manual Conventions

This manual identifies potential

hazards and has safety messages identified by the safety-alert symbol,

which signals a hazard that may cause serious

injury or death if you do not follow the recommended precautions.

G405934

This manual uses 2 words to highlight

information. Important calls attention

to special mechanical information and Note emphasizes

general information worthy of special attention.

Safety Alert Classifications

The safety-alert

symbol shown in this manual and on the machine identifies important

safety messages that you must follow to prevent

accidents.

Safety-alert symbol appears above

information that alerts you to unsafe actions or situations and is

followed by the word DANGER, WARNING,

or CAUTION.

|

Danger |  |

Danger indicates an imminently

hazardous situation which, if not avoided, will result in death or serious injury.

|

Warning |  |

Warning indicates a potentially

hazardous situation which, if not avoided, could result in death or serious injury.

|

Caution |  |

Caution indicates a potentially

hazardous situation which, if not avoided, may result in minor or moderate injury.